Case Studies

Published on Aug. 16th 2023

3D Scanning for Bus Partition Renovation and Noise Reduction

This article discusses how Ecuadorian 3D tech provider BSTAR used 3D scanning for bus partition renovation. They 3D scanned the problematic part with the EinScan HX and redesigned it in Solid Edge.

This article discusses how Ecuadorian 3D tech provider BSTAR used 3D scanning for bus partition renovation. They 3D scanned the problematic part with the EinScan HX and redesigned it in Solid Edge.

Introduction

Bus drivers in Quito, Ecuador, are exposed to excessive noise on the job due to poorly designed parts in their cockpit. It’s been affecting their work conditions for years, and the problem is present on hundreds of the city’s buses.

The municipality therefore reached out to BSTAR, an Ecuadorian tech service provider, to find a cost-effective solution. BSTAR’s engineer’s used the SHINING 3D EinScan HX and Solid Edge for this challenge.

One of Quito city’s 800+ buses.

One of Quito city’s 800+ buses.

- Name: BSTAR (BSTARTECHNOLOGY S.A.)

- Product: 3D scanning and design service, 3D printer supply

- Location: Quito, Ecuador

- Need: Redesign an unfit, rattling partition that was causing excessive noise

- Solutions: EinScan HX and Solid Edge

- Result: Fast and efficient design of a new partition with a tight fit

Faulty Design Affects 800 Buses and Drivers

The bustling capital city of Quito is home to over 2 million inhabitants. Its public transportation system features several options: metro lines, railways, bicycle sharing, and buses.

The bus system “Metrobus-Q” is a popular option. Over 800 buses roam the city to cater to its 750,000 daily passengers. It’s the backbone of the city’s transportation system, and an excellent option for its users.

However, on the drivers’ side, the buses pose a serious problem.

Each bus has partitions next to the front seat, destined to separate and protect the driver from the crowd. The issue is that these partitions don’t properly fit the cockpit. This faulty design results in an excessive rattling noise that the drivers must withstand 8 hours a day.

It’s been affecting their hearing and well-being for years, and it’s present on each of the 800 buses. The municipality of Quito decided to contact the BSTAR team for a complete redesign of the partitions.

The bus cockpit and the partitions.

3D Scanning for Bus Partition Renovation

To eliminate the rattling noise, BSTAR needed to accurately measure the cockpit and design a custom-fit partition. They decided to use the SHINING 3D EinScan HX 3D scanner for the measuring part.

This handheld 3D scanning solution was ideal for this case for several reasons.

For one, it was easy to bring on the bus; no tripods or complex setups involved. Its portability also enabled the technician to access the narrow spaces all around and under the driver’s seat.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

3D scanning for bus partition renovation was definitely a more efficient option than manually measuring the area. Plus, manual measurements leave room for error, as the bus drivers can testify.

After a quick 3D scanning session about only 3 hours (includes unneeded parts removal, markers pasting and 3D scanning), BSTAR’s technician obtained a clean, accurate 3D point cloud of the cockpit:

The resulting 3D scanned data of the cockpit.

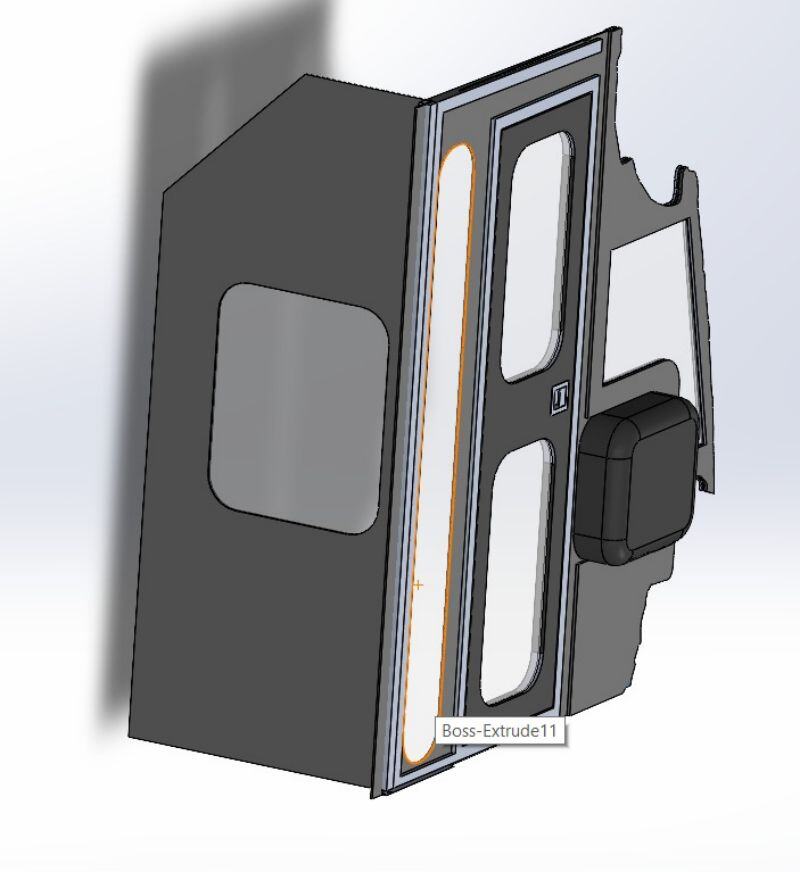

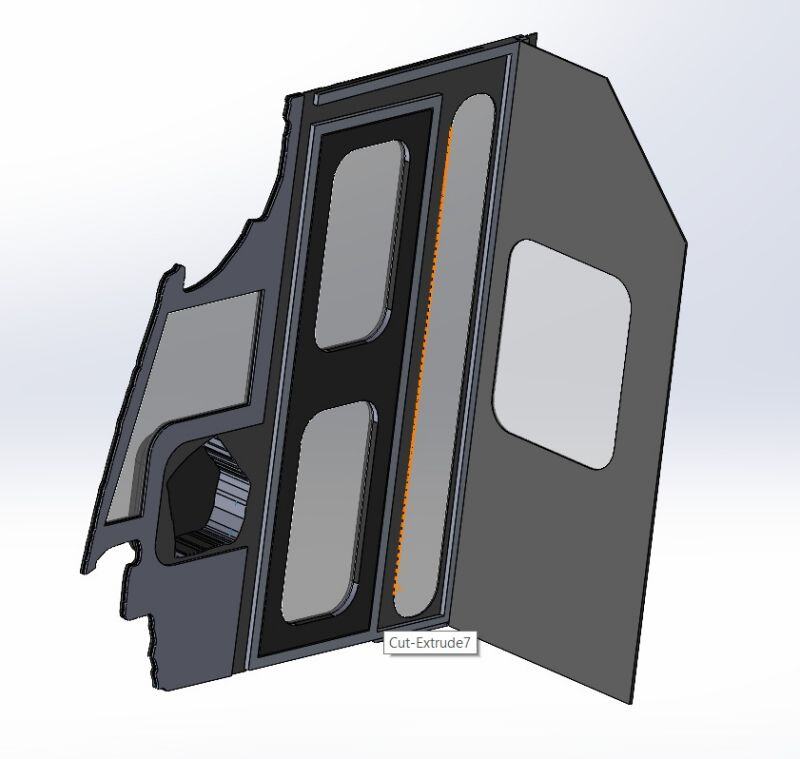

The team then exported the data to Solid Edge, a powerful 3D design software solution. With this data, they were able to redesign the bus partition. They made sure to design one that was the correct size and that would not cause any noise nuisance to the drivers.

Redesigned cockpit partition

Conclusion

Quito bus drivers could no longer stand the incessant noise coming from the poorly designed partitions. It was truly affecting their hearing and well-being at work, and the nuisance was present on hundreds of buses.

Thanks to 3D scanning and CAD software, the BSTAR team was able to remodel the partitions and ensure a more comfortable working environment for the drivers. The EinScan HX’s portability and precision, along with Solid Edge’s powerful design tools, were essential allies for this task.

Do you need to optimize critical parts in your field of work? Reach out to our application specialists for a free consultation, and see how our precise and efficient 3D scanners can help.

EinScan HX

The EinScan HX’s hybrid laser and LED light sources offer unmatched versatility, accommodating various object sizes effortlessly. With its efficiency and reliable results, EinScan HX unlocks endless application possibilities.

- Material Adaptability

- Reliable Results

- High Efficiency