Aerospace

Manufacturing complex structural components in aerospace is challenging. SHINING 3D scanners facilitate the efficient capture of 3D models for 3D printing and reverse engineering, providing robust solutions for the mass production of complex and customized parts.

Overview

About Our Metrology Solutions

Aero Engines

SHINING 3D high-precision laser scanners provide a non-contact solution for the design, reverse engineering, and inspection of aero engines. Multiple laser line modes capture 3D data on complex structures with ease, including deep holes, pipelines, curved surfaces, and more.

Aircraft & Airframes

We offer large-scale industrial 3D scanning solutions for aircraft and airframe measurement. The Track series 3D scanners quickly capture 3D data from aircraft without the need for target points. Equipped with blue laser technology, these scanners efficiently handle reflective and dark surfaces, offering accuracy, convenience, and efficiency.

Surface Inspection

Our 3D scanners enable precise identification of surface defects, imperfections, and irregularities on aerospace components, ensuring high-quality standards and reliability.

What You Can Achieve with Our Scanners

Discover the ways in which integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

Blade Inspection

Our 3D scanners are used to accurately measure and analyze the geometry of turbine blades, identifying surface defects, wear, and deformation to ensure optimal performance and safety.

-

Structural Inspection

Our 3D scanners are utilized to create detailed digital models of aircraft structures, allowing for the precise detection of cracks, corrosion, and deformations to ensure structural integrity and safety.

-

Aircraft Inspection

Our 3D scanners are employed to accurately capture the geometry of interior spaces, ensuring proper fit and alignment of components, and identifying wear or damage for maintenance and refurbishment.

-

Manufacturing Inspection

Our 3D scanners are used to verify the dimensional accuracy and quality of manufactured parts, ensuring they meet design specifications and identifying any deviations or defects early in the production process.

-

FreeScan UE Pro

Professional metrology handheld scanner with 26+7+1 blue laser lines and built-in photogrammetry for scanning different sizes and global precision control of large-scale workpieces.

-

Scan Accuracy

Up to 0.02 mm -

Volumetric Accuracy

0.02+0.015 mm/m -

Scan Speed

1,850,000 points/s -

Point Distance

0.01 ~ 10 mm -

Maximum FOV

600 x 550 mm -

Material Adaptability

Normal/Dark/Reflective -

Type of light source

Laser -

Align Mode

Marker Alignment

-

-

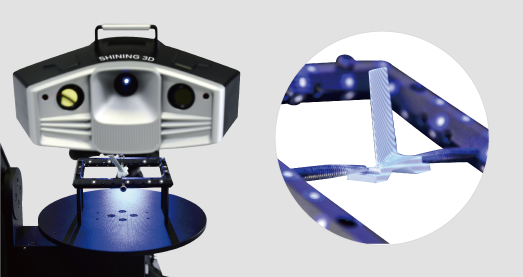

OptimScan 5M Plus

Blue light, high-precision 3D scanner for inspection, with 3 sets of lenses for flexible range switching.

-

Scan Accuracy

0.005 ~ 0.015 mm -

Volumetric Accuracy

/ -

Scan Speed

/ -

Point Distance

0.04 ~ 0.16 mm -

Maximum FOV

100 x 75 / 200 x 150 / 400 x 300 mm

-

Material Adaptability

Normal/Dark/Reflective -

Type of light source

LED -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan Trak Pro2

A metrology-grade optical tracking 3D scanning system for medium and large objects without markers. It is suitable for various static and dynamic applications.

-

Scan Accuracy

Up to 0.023 mm -

Volumetric Accuracy

0.062 mm -

Scan Speed

3,070,000 points/s -

Point Distance

0.05 ~ 10 mm -

Maximum FOV

650 x 580 mm -

Material Adaptability

Normal/Dark/Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-

-

FreeScan Trio

Flagship metrology handheld scanner with fast and innovative 98 laser lines for marker-free scanning. Whether you need speed or accuracy on small or large assemblies, the versatile FreeScan Trio is geared for all your projects.

-

Scan Accuracy

Up to 0.02 mm -

Volumetric Accuracy

0.02+0.015 mm/m -

Scan Speed

3,010,000 points/s -

Point Distance

0.01 ~ 3 mm -

Maximum FOV

650 x 580 mm -

Material Adaptability

Normal/Dark/Reflective -

Type of light source

Laser -

Align Mode

Feature Alignment / Marker Alignment

-