Electronic & Electrical

Quality control process are critical for all aspects of circuit board and electronic device manufacturing processes to ensure compliance to design requirements, and accurate, reliable performance. Critical categories involve component, date and process.

Overview

About Our Metrology Solutions

Computer & Communication & Consumer Electronics

Computer, communication and consumer electronics Manufacturing industry is now one of the most important industries around the world. A typical process can be divided into four main phases: module manufacture, assembly, testing and packaging, with the latter three most dependent on human workers.

Electronics Manufacturing OEM

Electronics manufacturing services is a term used for companies that design, manufacture, test, distribute, and provide return/repair services for electronic components and assemblies for original equipment manufacturers.

Electronic Consumer Durables

Consumer electronics include devices used for entertainment, communications and recreation. These products are usually referred to as black goods due to many products being housed in black or dark casings.

What You Can Achieve with Our Scanners

Discover the ways in which integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

Enclosure Design

Our 3D scanners are instrumental in enclosure design by capturing precise measurements of components and internal layouts.

-

Tooling Inspection

Our 3D scanners are utilized for tooling inspection to verify the accuracy and quality of manufacturing tools, molds, and fixtures.

-

Tolerance Visualization

Our 3D scanners facilitate tolerance visualization by creating detailed digital models of components and assemblies.

-

Reverse Engineering

Our 3D scanners are pivotal in reverse engineering by accurately capturing the geometry of existing components and assemblies.

-

Root Cause Analysis

Our 3D scanners support root cause analysis by providing detailed geometric data of components.

-

Manufacturing Analysis

Our 3D scanners are utilized for manufacturing analysis by capturing precise measurements and geometric data of components and assemblies.

-

Transcan C

Ready-to-use dual-scan range for small to medium size with high resolution and high color fidelity.

-

Scan Accuracy

Up to 0.035 mm -

Volumetric Accuracy

/ -

Scan Speed

<3s -

Point Distance

0.0375 mm;0.075 mm;0.114 mm;0.154 mm;0.23 mm -

Maximum FOV

300 x 190 mm -

Material Adaptability

Normal -

Type of light source

LED -

Align Mode

Feature Alignment / Marker Alignment

-

-

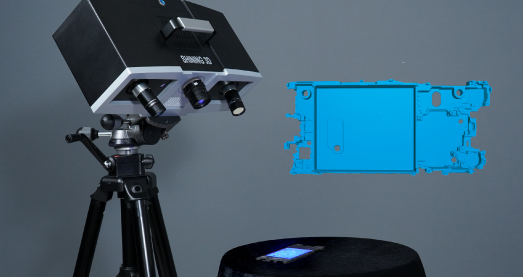

OptimScan 5M Plus

Blue light, high-precision 3D scanner for inspection, with 3 sets of lenses for flexible range switching.

-

Scan Accuracy

0.005 ~ 0.015 mm -

Volumetric Accuracy

/ -

Scan Speed

/ -

Point Distance

0.04 ~ 0.16 mm -

Maximum FOV

100 x 75 / 200 x 150 / 400 x 300 mm

-

Material Adaptability

Normal/Dark/Reflective -

Type of light source

LED -

Align Mode

Feature Alignment / Marker Alignment

-