Yes. With a built-in color camera, EinScan HX2 supports full-color texture capturing and tracking in rapid scan mode.

EinScan HX2

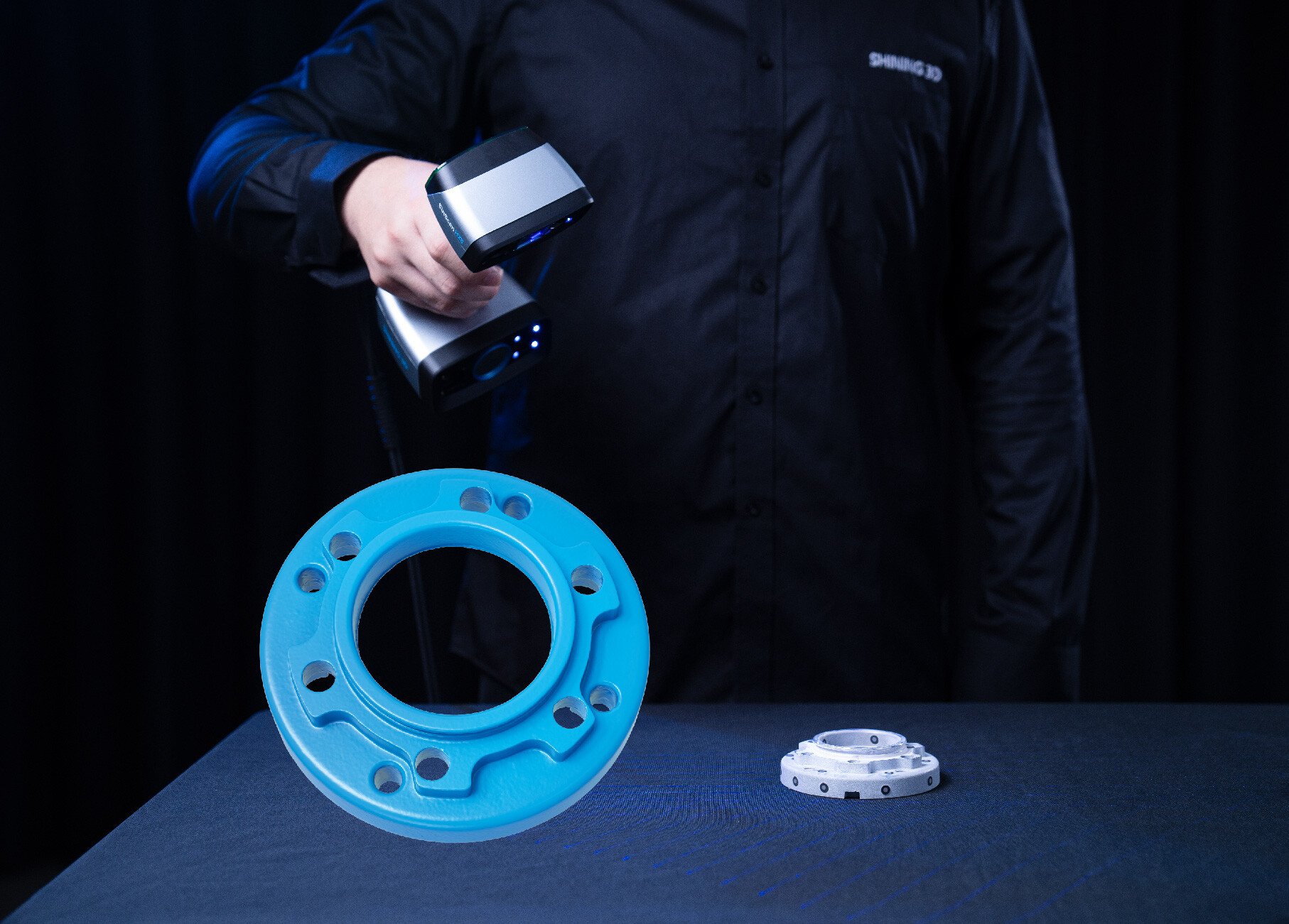

Retaining the hybrid laser and blued LED technology, the EinScan HX2 excels in accuracy, versatility, and ease of use.

- Accuracy up to 0.04 mm

- Minimum point distance of 0.05 mm

- 1,600,000 points/s and 120 FPS under laser scan mode

- Full Color

A Hybrid and Versatile Solution

The EinScan HX2 enhances its predecessor's features, now boosting 13 crossed blue laser lines for more detailed scanning and an increased frame rate of 120 FPS for faster scanning.

Hybrid Blue Laser & LED Light

High Efficiency

High Accuracy & Detail

Portable & Easy Operation

Full Color

Reverse Engineering Bundle

Hybrid Blue Laser & LED Light

High Efficiency

High Accuracy & Detail

Portable & Easy Operation

Full Color

Special Pricing for Reverse Engineering Bundle

What You Can Achieve with Our Scanners

Discover how integrating our scanners into your workflow can enhance efficiency and help you achieve remarkable results.

-

Automotive

Equipped with both laser and LED light sources, EinScan HX2 can scan parts with markers for testing the part's surface deformation and also fast scanning engines or automotive chassis without markers to redesign and modify.

-

Research & Education

EinScan HX2 enriches educational experiences and accelerates research by effortlessly digitizing objects into detailed 3D models, fostering innovation in 3D printing, and product prototype design.

-

Cultural Creation & Art Customization

EinScan HX2 preserves artifacts and landmarks with remarkable detail and color, and accurately digitizes them into immersive 3D models, ensuring their legacy endures with precision and authenticity.

EXScan HX Software

Your EinScan HX2 comes with access to our powerful and continuously updated EinScan software. Scan as much as you want, all year long, with no hidden fees or extra costs.

Step-by-step Guidance

EXScan HX software will guide you through the 3D scanning process, from calibration to 3D scanning and data editing.

Smart Data Process

EXScan HX software is equipped with intelligent algorithms that can process and optimize scanning data more efficiently, and output more ideal results.

Regular Updates

Ensure your software stays up to date with regular updates. Stay in the loop with updates, which collaborate to enhance your hardware performance.

Supports Multi-languages

In addition to English, our software supports German, Japanese, Korean, Russian, French, Spanish, and Traditional Chinese. This list is continuously being updated

EinScan HX2 Tech Specs

- Accuracy Up to 0.04 mm

- Volumetric Accuracy up to 0.04 + 0.06 mm/m

- Point Distance 0.25 ~ 3 mm

- Scan Speed Up to 1,600,000 points/s

- Max. FOV 420 x 440 mm

- Working Distance 470 mm

- Align Mode Feature / Markers / Texture / Hybrid

- Light Source Blue LED / 13 Blue Laser Crosses

Our Expertise, Your Advantage

years of experience

patents

3D scanners sold Worldwide

-

Recently I did a job on a large motor yacht and I had to scan the pantograph doors. So the doorways to have a client in Italy design new doors for those. They're big parts measuring 2x1 meters. I had 5 doors to do on the vessel and they took about 45 minutes each. That was fast.

EinScan HX is really easy to use, intuitive, and it gives great results. Very accurate.Warrick,

Coda Enhance Design Company, Australia

-

The EinScan HX can use both laser and structured light, which helps us solve a variety of different types of projects and also helps us speed up our design work.

Chris Carpenter ,

Italian Design and Racing

-

EinScan HX helped us to get the whole information of large murals precisely and quickly, which is very convenient. In the future, 3D scanners may become standard equipment for all murals or even cultural heritage restoration and conservation work.

Director Cao,

the Cultural Property Conservation Center of the Ningbo Finance and Economics Institute

Frequently Asked Questions

-

Can EinScan HX2 do fixed scanning?

EinScan HX2 is perfect for medium to large 3D scanning of dark surfaces and metal industrial parts. For handheld and small jobs, check our guide.

-

Can EinScan HX2 capture color data?

Yes. EinScan HX2 has a built-in color camera. You can get the full color data in rapid scan mode.

-

What are the applications of EinScan HX2?

By integrating blue light and laser, EinScan HX2 can be used in a wide range of applications with less limitation. Up to 1,600,000 points/s under laser scan mode enable EinScan HX2 to scan large objects with high efficiency. Laser scanning technology enables EinScan HX2 to an amazing performance in scanning reflective and dark objects. Minimum point distance of 0.05mm and up to 0.04 accuracy make EinScan HX2 suitable for reverse engineering and measuring. We could say EinScan HX2 is a powerful scanner for applications, such as automotive, mold manufacturing, research & education, art & culture.

-

Is it possible to scan without pasting markers on object?

Yes. If the object has rich geometric features, you can use feature alignment. Alternatively, if you have a turntable attached, you can also use turntable alignment.

-

Is it possible to scan color texture of objects?

-

Can EinScan HX2 scan black and reflective surface objects?

Yes. EinScan HX2 has laser scan mode, which is less sensitive to ambient light and thus delivering better performance in scanning reflective and dark colored surfaces.

-

What is the recommended computer configuration for EinScan HX2?

OS: Win10/11, 64-bit; Graphics card: NVIDIA RTX3060 or better; Video memory: ≥6GB; Processor: Intel i7-12700 or better; Memory: ≥32GB -

What are the post-processing functions of ExScan HX2?

Data simplification, hole filling, smooth, sharpen, cutting-plane selection and removal, measurement, movement, texture optimization. The digital toolkit comprising EXScan Scanning Software, SolidEdge SHINING 3D Edition and Geomagic Essentials coming to you with your new EinScan HX2will upgrade your 3D digital workflow significantly!

-

How to scan a very thin object?

Thin objects are very tricky as you can have interference between the 2 faces, causing a misalignment of data. It is recommended to scan global markers first to improve the accuracy of alignment.

-

When do I need to calibrate the scanner?

1. When the scanner is used for the first time, or when it is reused after being laid idle for a long period of time (1 -2 weeks).

2. The scanner was severely shaken or vibrated, such as shaken during transportation.

3. Severe accuracy reduction, such as frequent errors in alignment or unrecognized markers.

4. Incomplete data is acquired during the scanning or serious deterioration of the quality of scanned data.

Trusted Worldwide

Let's explore why SHINING 3D is the go-to choice for experts across various industries.