Case Studies

Discover our latest resources

Filter posts:

-

A Look At A Full-Dimensional Inspection Workflow With 3D Scanning

With cutting-edge technology like 3D scanning, manufacturing service providers can have a significant competitive advantage. They can set their quality standards higher and deliver faster, tighter fits right from the first prototype. “I was deeply impressed when we went to a foreign customer’s site and they used their 3D scanner to perform 3D inspection. The customer’s inspection report was almost exactly the same as ours! Our customer was very satisfied, and so were we.” -Chairman at the manufacturing company

Learn More -

FreeScan Combo in Cultural Heritage Restoration: 3D Replica of Tiangong Furnace

This article explores the importance and benefits of 3D scanning for cultural heritage preservation.

Learn More -

Aircraft Manufacturer Uses FreeScan UE Pro for Sailplane Quality Control

When aircraft manufacturers need to perform sophisticated quality control and document their handcrafted structures for future use in design and modification, they understand that handheld 3D scanners will be the ultimate answer.

Learn More -

3D Measurement for New Energy Vehicle Battery Packs

Discover how optical 3D metrology enhances the accuracy and efficiency of battery pack manufacturing for new energy vehicles, ensuring quality and reliability.

Learn More -

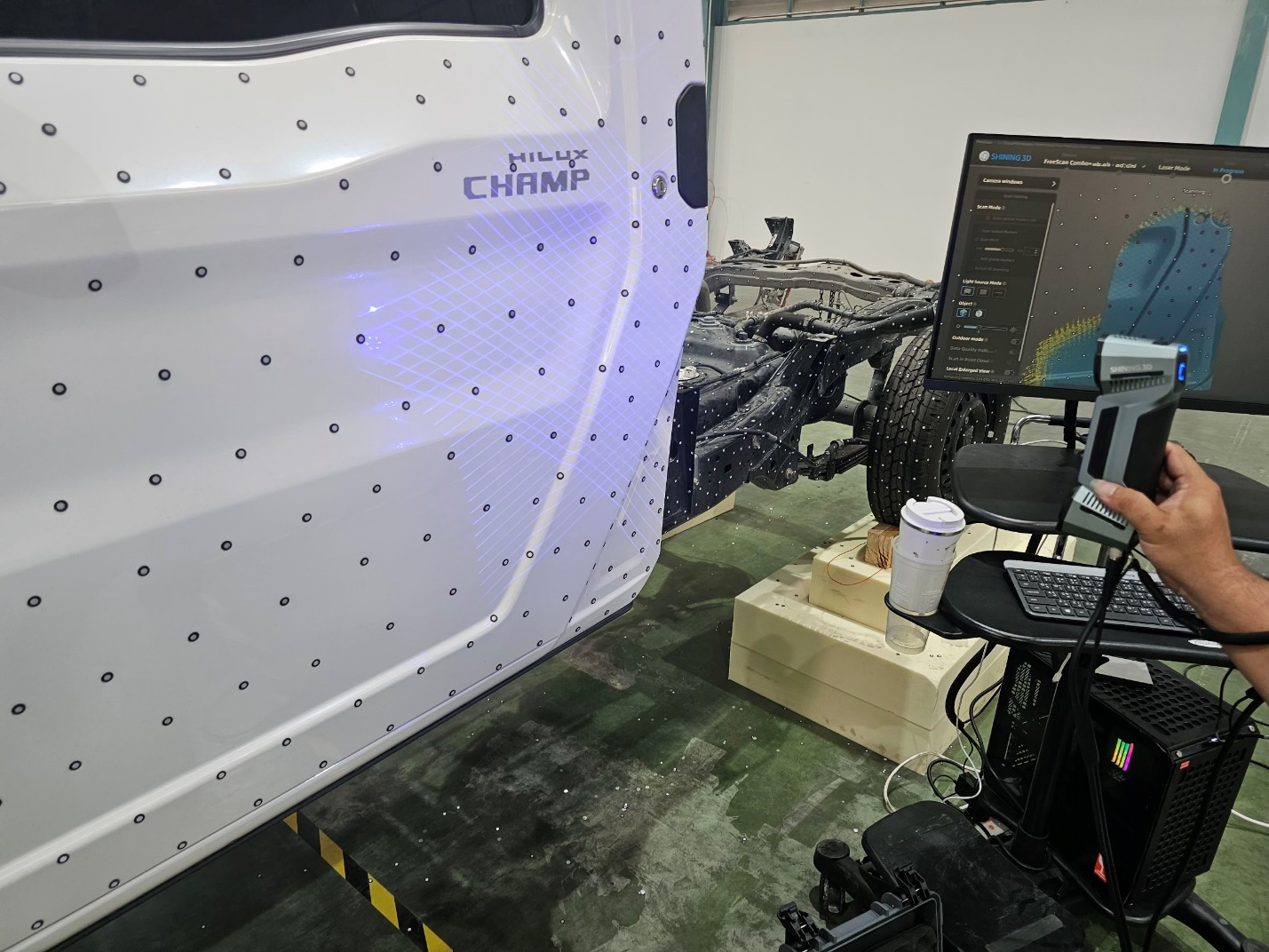

Advancing Camper Van Manufacturing with SHINING 3D FreeScan Combo Series

This case introduces how VANTECH enhanced its camper van manufacturing process by adopting SHINING 3D's FreeScan Combo series.

Learn More -

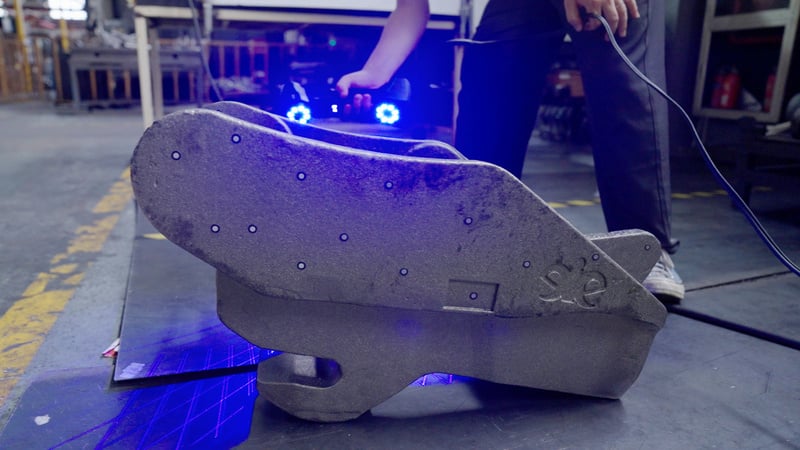

Solving Machining Benchmark Misalignment with SHINING 3D: Boost Product Qualification to 99.5%

In casting, even small misalignments can lead to costly defects. By using high-accuracy 3D scanning, a metal casting company can inspect blanks, simulate machining benchmarks, and detect boss offsets, minimizing errors from traditional methods.

Learn More -

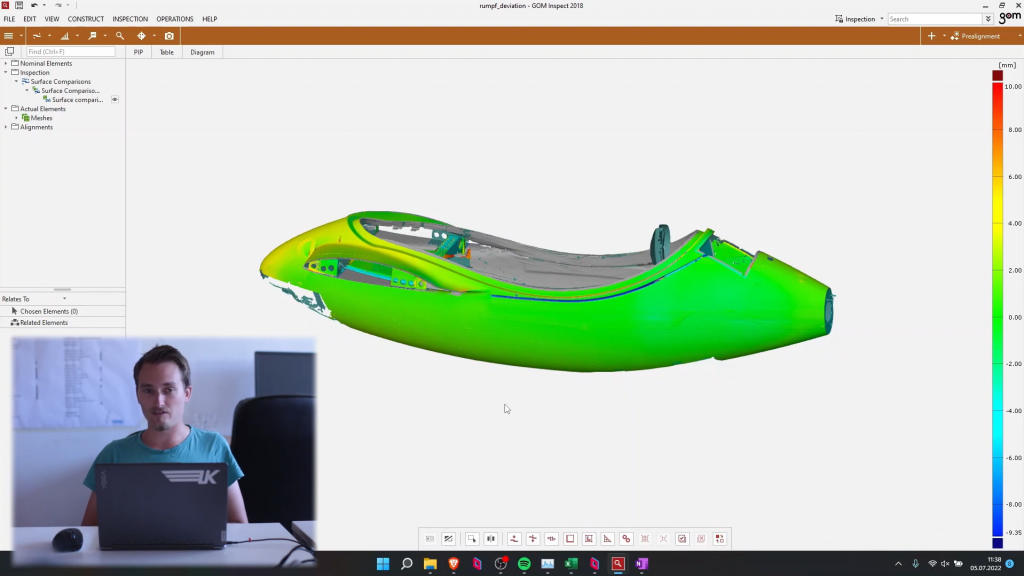

Prototype Inspection Using FreeScan Combo and Geomagic Control X Software at the TDK sv

The production unit of TDK's Szombathely factory, specialized in developing and manufacturing electromagnetic interference (EMI) filters, turned to SHINING's 3D scanners to check the dimensions of their increasingly complex products to meet evolving customer demands in a quicker and most effective way.

Learn More -

How SHINING 3D Scanners Empowered Reverse Engineering and Developing Capability of Mining Equipment Parts

This case study highlights how SHINING 3D scanners have streamlined GL Equipamentos' workflow, improved the accuracy of reverse engineering, and provided faster, more reliable services to clients in the mining industry.

Learn More -

SHINING 3D Empowers TJURacing in Formula SAE Competition Preparation

Through a collaboration with SHINING 3D, the TJURacing team introduced high-accuracy 3D scanning technology to enhance race car manufacturing efficiency and quality control.

Learn More