Case Studies

Published on Jan. 1st 2024

3D Scanning and Reverse Engineering for Ship Maintenance

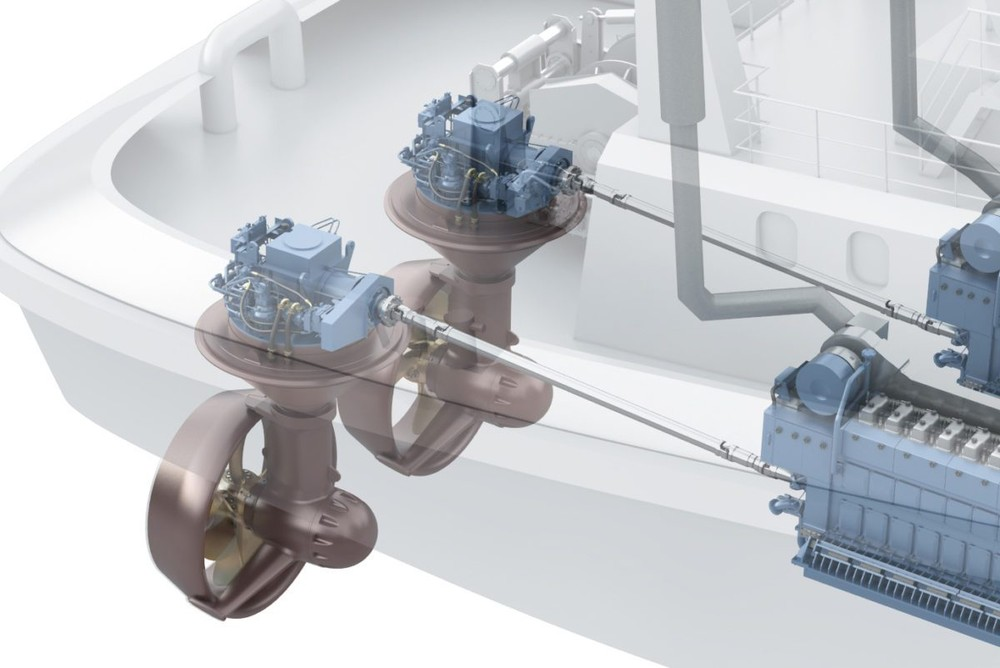

This article discusses how the FreeScan UE Pro 3D scanner assisted in repairing rotary gears on a tugboat’s steering column. The client for this post operates in offshore operations, including providing tugboat services, escorting tankers, and delivering pilotage services.

The integration of 3D scanning for ship maintenance has become increasingly pivotal in the maritime industry, because ship maintenance plays a crucial role in ensuring the safety, transportation efficiency, and longevity of ships. Traditional methods of assessing and repairing ships often involve manual measurements, drawings, and physical prototypes. However, with the advancement of technology, there has been a significant shift towards more precise, efficient, and cost-effective maintenance practices.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

Challenge: Large and Heavy Gears

The rotary gear on the steering column replaces the ship’s steering wheel, which rotates 360° and allows you to maneuver in cramped conditions. When the rotary gear malfunctions, it not only impacts the ship’s maneuverability but also poses risks during docking operations and long-distance icebreaker towing.

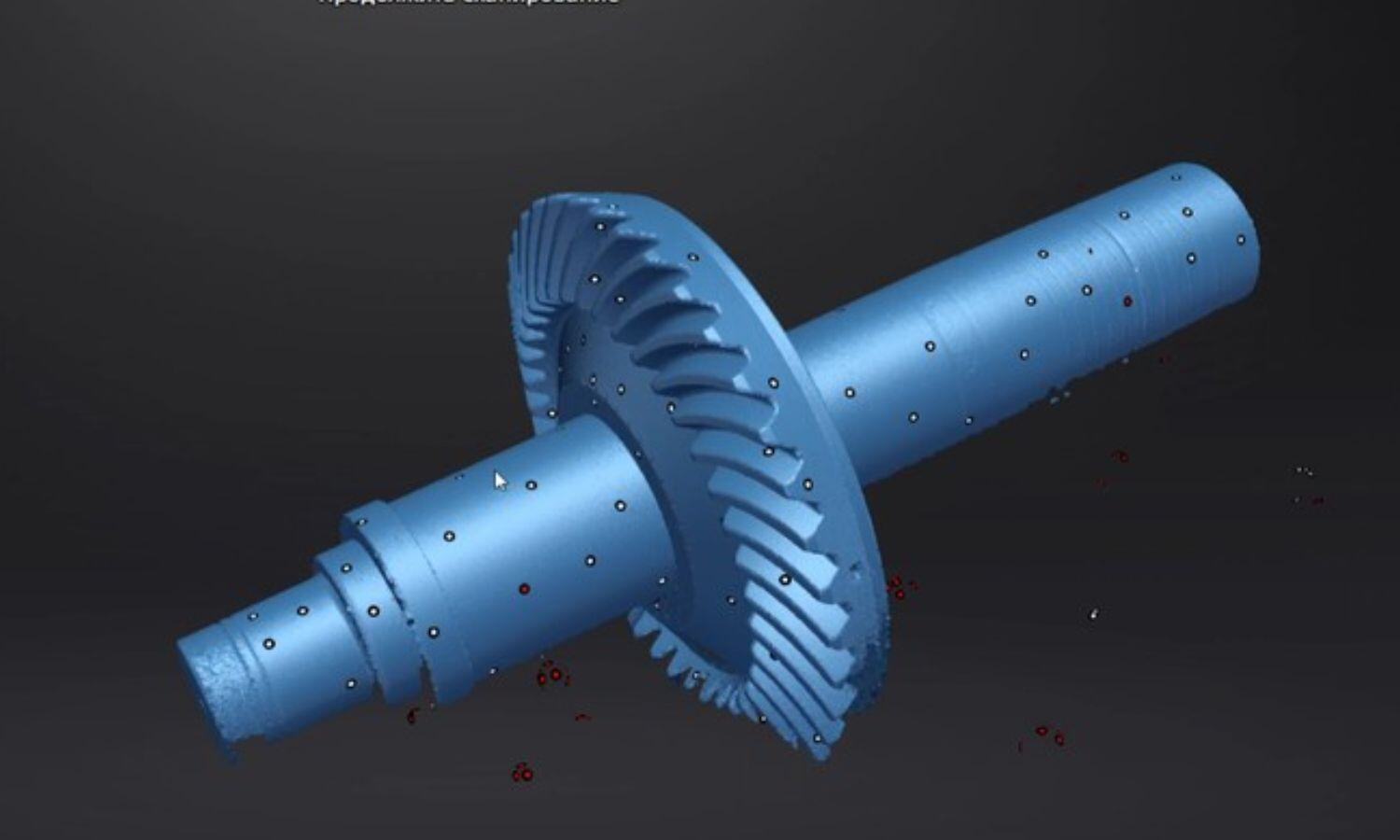

Gears are typically large to handle greater torque and force, ensuring adequate maneuverability and stability during ship operation. At the same time, rotary gears often have complex geometries such as gear profiles, internal bores and threads.

Manual measurements and physical prototypes find capturing these components challenging due to their complex geometries and precise specifications. Moreover, the sheer size and weight of these gears make it difficult to handle and manipulate them accurately during the repair process. These limitations highlight the necessity of adopting advanced technologies like 3D scanning for a more efficient and accurate approach.

Solution: FreeScan UE Pro

The FreeScan UE Pro features 26+7+1 blue laser lines and includes built-in photogrammetry to handle various scanning scenarios. The scanner has an accuracy of up to 0.02 mm. It is ideal for capturing detailed scans of large and heavy components in offshore equipment.

Using Markers and Sprays

First, our client removed the bearings from the shafts, degreased them, put the markers, and applied a matting spray. Markers help the scanner in understanding the part’s spatial orientation, while the spray eliminates laser beam distortion.

3D Scanning and Reverse Engineering for Ship Maintenance

Utilizing laser scanning modes, including 26 cross lines for global scans and single line mode for deep holes, ensured comprehensive data capture. Additionally, fine scan mode (7 parallel lines) was used for critical areas like gear tooth profiles and threaded holes, boosting point distance to 0.1 mm for precise data capturing. Upon completing the scans, the team embarked on reverse engineering the captured models.

3D scanning for ship maintenance-horizontal shaft

Results

The final CAD models derived from these scans proved invaluable for both the repair and replication of the damaged components. The company can now create necessary maintenance parts ahead of time for timely replacement, thus reducing downtime and costs linked to sourcing and manufacturing replacement parts.

Conclusion

In conclusion, the adoption of the SHINING 3D FreeScan UE Pro scanner marks a transformative step in ship maintenance. It offers a high-precision solution to the complex challenge of repairing tugboat steering gears. Further embracing such technologies ensures continuous improvement in ship maintenance processes, enhancing the sustainability and reliability of maritime operations.

FreeScan UE Pro

FreeScan UE Pro equips high-precision, metrology-grade accuracy and lightweight design while improving the ability to fine-scan and global precision control large-scale workpiece scanning.

- Metrology-Grade High Accuracy

- Global Precision Control

- Multiple Scanning Modes