CASE STUDIES

Published on Mar. 13th 2025

Advancing Camper Van Manufacturing with SHINING 3D FreeScan Combo Series

This case introduces how VANTECH enhanced its camper van manufacturing process by adopting SHINING 3D's FreeScan Combo series. By upgrading 3D scanning technology, VANTECH significantly reduced costs, improved scan accuracy, and boosted productivity—achieving faster processing for vehicle design and production.

This case introduces how VANTECH enhanced its camper van manufacturing process by adopting SHINING 3D's FreeScan Combo series. By upgrading 3D scanning technology, VANTECH significantly reduced costs, improved scan accuracy, and boosted productivity, achieving faster vehicle design and production processing.

- Name: VANTECH Co., Ltd.

- Size: 100 employees (Thailand factory)

- Location: Samutprakarn, Thailand

- Product: Camper vans

- Need: Upgrade 3D scanner to improve productivity

- Solution: SHINING 3D FreeScan Combo series

- Results:

- Reduced outsourcing cost by around 600,000 ~ 2,400,000 baht

- Reduced errors during the scanning process, satisfied manufacturing accuracy

- Reduced scanning and data processing time, improved productivity

About VANTECH

VANTECH, a renowned company in Japan, has established its own car brand. As a pioneer in the development and production of camper vans, VANTECH's goal is to create a culture of camper vans that will make these vehicles a common sight on Japan's roads.

With a dedicated R&D team in Thailand, VANTECH focuses on the design and engineering of car extensions. The team relies heavily on 3D scanning technology to capture data for reverse engineering, which is then processed into CAD files for manufacturing.

VANTECH company

The Challenge

For the past decade, VANTECH has been using 3D scanners in its design and manufacturing process. While the technology had served them well in the past, the company faced several challenges:

- Limitations in scanner performance and accuracy: Due to scanner performance limitations, VANTECH used to have to create multiple scanning projects to acquire data for an entire vehicle. “We don't tend to split scans into several parts because aligning these files loses accuracy, which is not what we expect,” said one engineer.

- Cost and Time Constraints: To cope with scanner performance and scanning speed limitations, VANTECH had to outsource the scanning of vehicles to third-party suppliers. This outsourcing process not only added significant cost to the production cycle but also impacted the overall timeline. Fees ranged from 50,000 to 200,000 THB per scan depending on the car's complexity, and VANTECH needed at least one vehicle scanned every month.

The Solution

VANTECH had been familiar with SHINING 3D’s products for some time and had built trust in the brand’s quality and innovation. After careful evaluation, the company selected the FreeScan Combo series for its:

- Advanced Scanning Performance: Equipped with both blue laser and infrared light, the scanner optimizes data capture. The blue laser excels in capturing intricate car features with precision, while the infrared light efficiently scans large surfaces. Three scanning modes under the blue laser ensure a balance between comprehensive data acquisition and fine details. Intelligent software algorithms further enhance data collection and processing efficiency.

- High Accuracy: With an accuracy of up to 0.02 mm, the FreeScan Comboseries delivers accurate scan data to minimize errors in reverse engineering and manufacturing.

- Seamless Software Compatibility: Fully integrates with leading reverse engineering software, including SHINING 3D’s EXModel, enabling precise CAD data for smoother design-to-manufacturing workflows. This improves data processing and model creation, reducing turnaround time for vehicle design and production.

- Award-Winning Design: Recognized with the Red Dot award, the FreeScan Combo series assured VANTECH of its quality and reliability. Its lightweight design made full-vehicle scans easier.

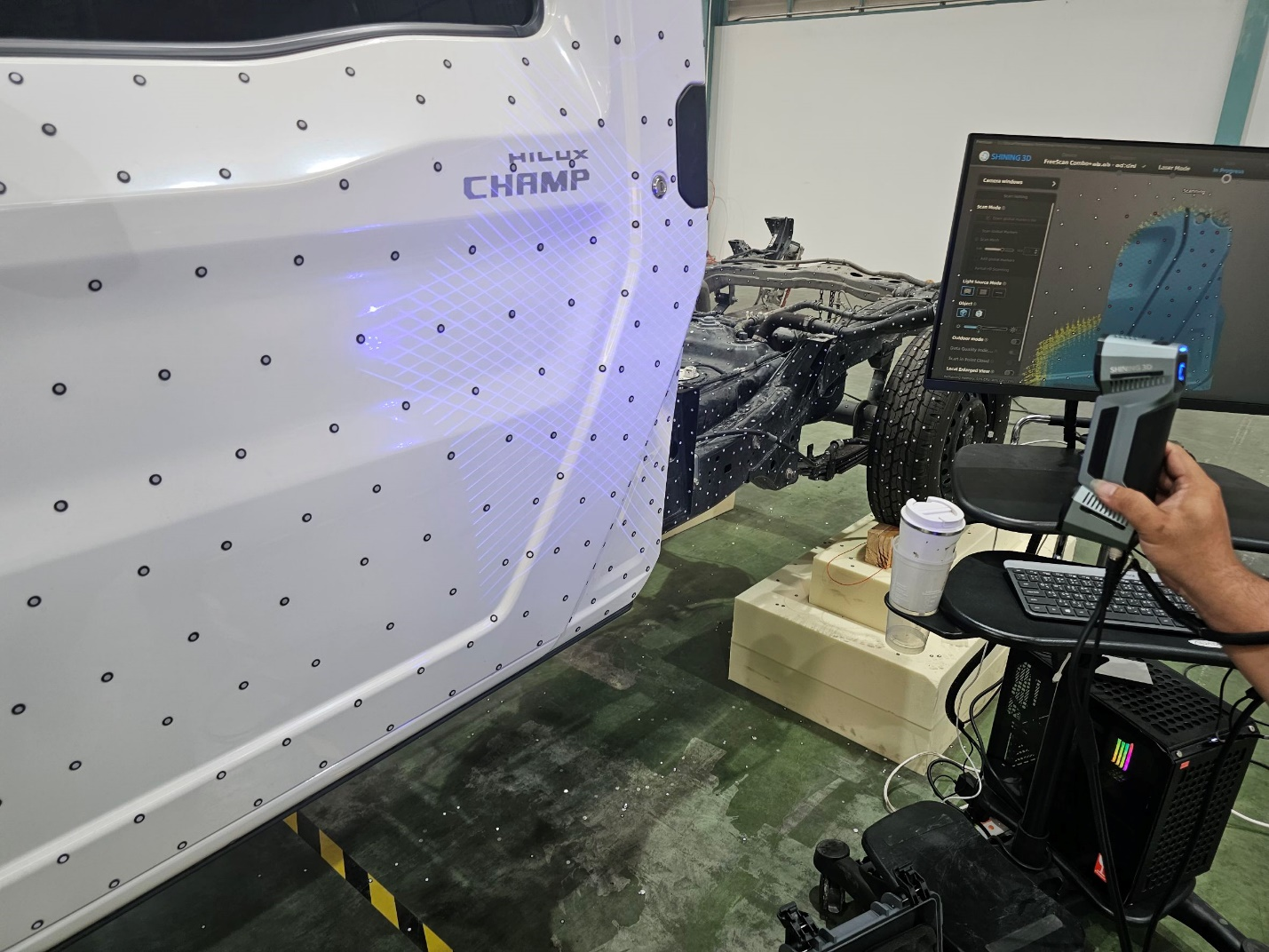

3D Scanning the car body with FreeScan Combo series

Additionally, VANTECH values strong customer support. SHINING 3D’s pre-sales guidance and post-sales assistance played a crucial role in the decision, ensuring VANTECH could maximize the efficiency of its new scanning solution.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

Results

By adopting the SHINING 3D FreeScan Combo series, VANTECH has seen notable improvements in both operational efficiency and cost-effectiveness:

- Cost Reduction: In-house vehicle scanning eliminates outsourcing expenses, saving VANTECH 600,000 ~ 2,400,000 THB annually.

- Improved Accuracy: The FreeScan Combo series minimizes scanning errors, ensuring higher-quality data for superior vehicle design and manufacturing accuracy.

- Faster Scanning Process: The time required for scanning has been significantly reduced, leading to faster turnaround times for vehicle designs and production schedules.

Scanned data display in FreeScan software

Now, VANTECH can streamline its manufacturing process and continue its mission of making camper vans a mainstream vehicle in Japan. With the combination of advanced technology, cost savings, and outstanding customer support, VANTECH is now well-positioned to continue leading the charge in the camper van industry.

FreeScan Combo

The powerful FreeScan Combo packs dual light sources in an ultra-compact shell, measuring just 193x63x53mm. It's equipped with both blue laser and infrared VCSEL technology and weighs in at only 620g.

- Blue laser & Infrared light

- 4 Scanning modes to cover all types of workpieces

- Lightweight