Case Studies

Published on Nov. 30th 2024

H7 Metrology: Efficient Reverse Engineering and Quality Control with FreeScan UE Pro

This case study explores how H7 Metrology, specializing in the industrial quality sector, overcame the challenge of handling complex object geometries to enhance its quality control processes.

Introduction

This case study explores how H7 Metrology, specializing in the industrial quality sector, overcame the challenge of handling complex object geometries to enhance its quality control processes. The company achieved superior accuracy, reliability, and cost-effectiveness by integrating the SHINING 3D FreeScan UE Pro scanner into its operations.

About H7 Metrology

Founded in 2022, H7 Metrology specializes in dimensional controls, non-destructive testing, reverse engineering, and manufacturing parts and models. Based on its expertise, the company addresses the growing demand for verification, metrology, and quality control in industrial processes.

Challenge: How to Make Object Handling Easier?

H7 Metrology’s primary challenge lay in handling parts with complex geometries, which made dimensional verification difficult and time-consuming. The company required a solution to guarantee precision, ensure reliability, and streamline quality control workflows without sacrificing operational efficiency or accuracy.

Solution: SHINING 3D FreeScan UE Pro

To overcome these challenges, H7 Metrology, with the guidance of Sicnova, incorporated the SHINING 3D FreeScan UE Pro into its operations.

This metrology-grade handheld blue laser 3D scanner offered exceptional accuracy, making it ideal for high-volume parts, reflective surfaces, and complex geometries. The scanner’s portability allowed the team to digitize and measure parts efficiently, even in remote or challenging locations.

With this 3D scanner, they have developed different projects, such as restoring electric vehicles that needed spare parts to keep the fleet running. In this case, the customer was located in Cancun (Mexico). Still, digitizing and measuring the parts remotely with a scanner considerably saves transport costs and time. For the development of reverse engineering applications, the 3D scanner offers the necessary portability to obtain most of the data necessary to create new parts.

They have also used the FreeScan UE Pro to perform dimensional checks on hot stamping plugs and ship propellers. For these large and complicated parts, the 3D scanner is the best tool to obtain a mesh that can be compared against CAD. With the FreeScan UE Pro, they can quickly verify tolerances in dimensional control.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

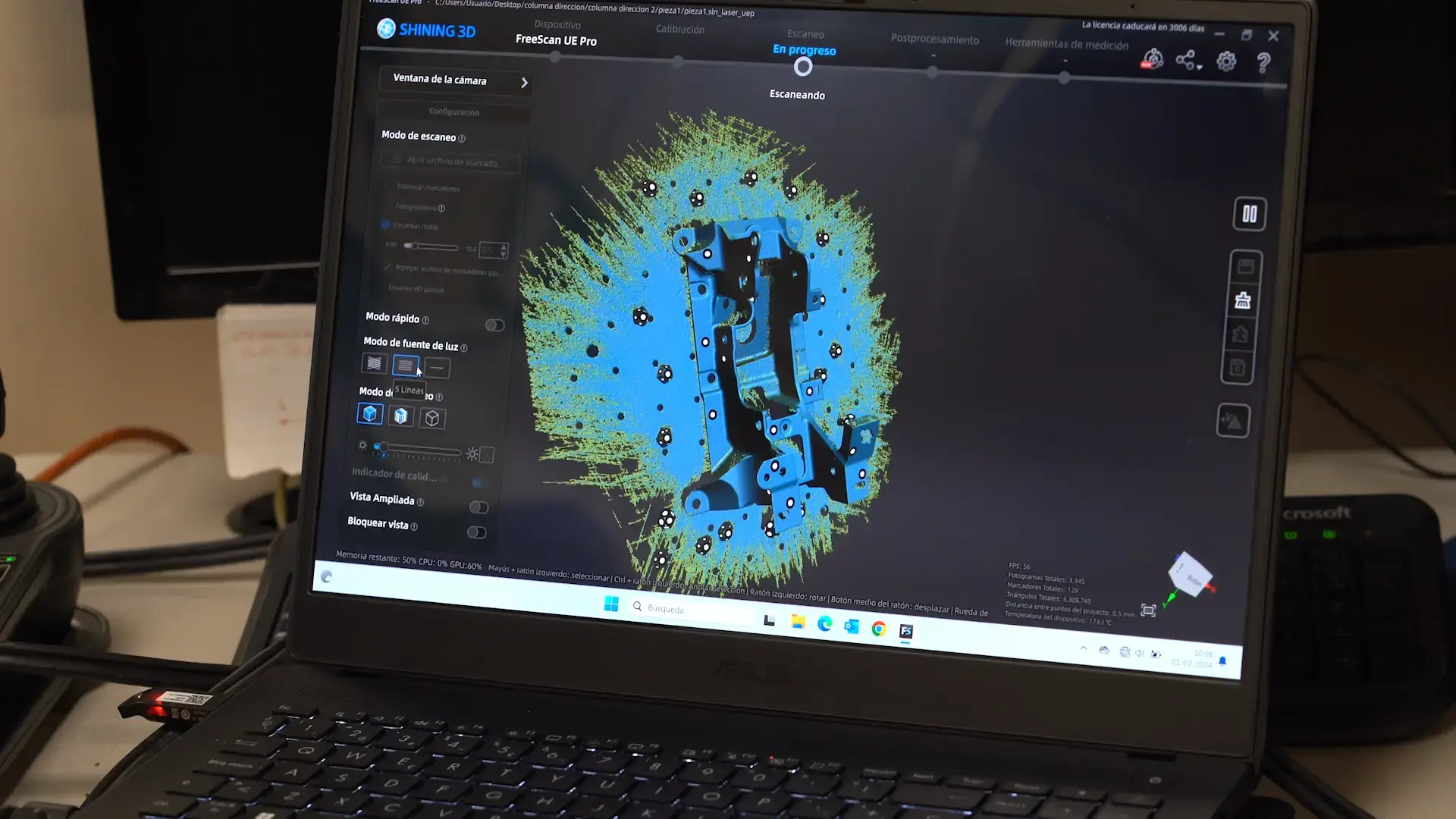

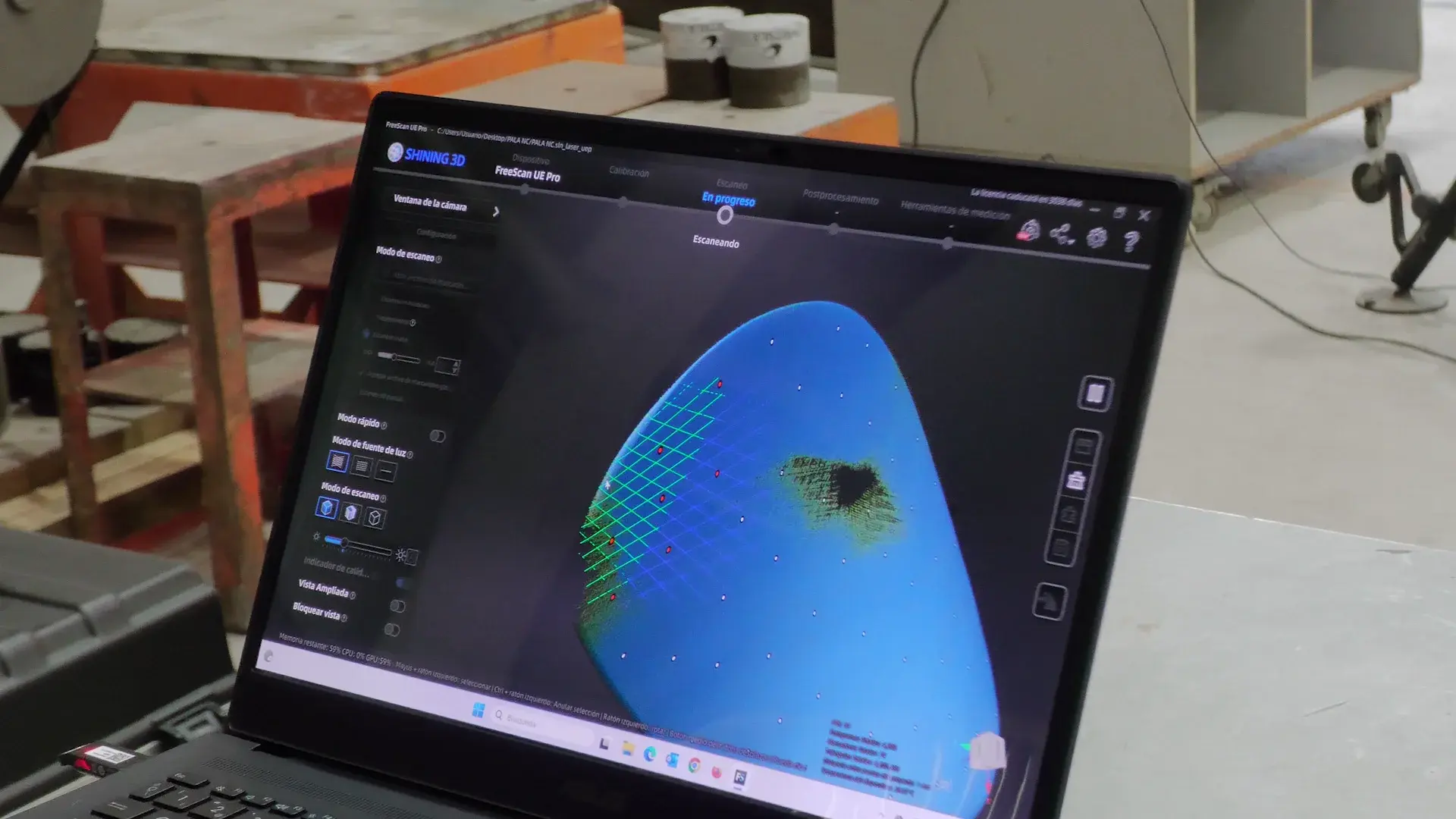

Scanning a part

Scanning a propeller blade

Result: Greater Quality Control Process

Adopting the SHINING 3D FreeScan UE Pro transformed H7 Metrology’s quality control capabilities. Key benefits included:

- Enhanced Accuracy: The scanner delivered reliable and precise measurements for complex geometries and surfaces.

- Time and Cost Savings: Streamlined processes reduced production times and eliminated unnecessary transport expenses.

- Improved Accessibility: Enabled measurements in challenging areas previously unreachable with traditional techniques.

- Higher Quality Standards: The tool ensured that products met stringent expectations, creating a competitive edge for high-quality outputs.

Scanning data

Scanning data

Are you looking to enhance your quality control and metrology capabilities? Contact us to discover how SHINING 3D scanners can transform your operations today.

FreeScan UE Pro

FreeScan UE Pro equips high-precision, metrology-grade accuracy and lightweight design while improving the ability to fine-scan and global precision control large-scale workpiece scanning.

- Metrology-Grade High Accuracy

- Global Precision Control

- Multiple Scanning Modes