Case Studies

Published on Nov. 4th 2024

How FreeScan Combo Helps Improve Automotive Exhaust Converter Inspection

Discover how YUTAKA Brazil managed to increase Automotive exhaust converter inspection and quality control efficiency with SHINING 3D FreeScan Combo, and reduce costs.

Introduction

YUTAKA was looking to improve its automotive exhaust converter inspection and quality control process. They used fixed 3D scanning, and this did not give them flexibility and speed. With the FreeScan Combo, they were able to achieve the objectives and challenges of the area.

Client: YUTAKA

Location: Brazil

Need: Efficiency, cost and time reduction in automotive exhaust converter inspection

Solution: SHINING 3D FreeScan Combo

Results:

- Lower total time and cost of inspection

- Increased efficiency and accuracy of inspection

About YUTAKA

Yutaka is a Japanese multinational company that supplies exhaust converters for vehicles and has met the challenge of creating products that contribute to preserving the global environment, such as automobile engine parts, exhaust systems, torque converters, and heat management device. Yutaka has done so on a global scale by employing our integrated system from research, through development and onto production under its slogan "Clean for the Future."

YUTAKA has been in Brazil since December 2001, and the Brazilian subsidiary has been specializing in the development and production of automotive exhaust converters, supplying automotive components to major OEMs such as Toyota, Honda and Nissan.

Continuous Improvement in the Inspection Area

YUTAKA was looking for solutions to improve and enhance their inspection and quality control process. Their existing process, with fixed 3D scanning, was very slow and not flexible, as the unit was fixed and could not be scanned at the customer's site. They contacted our local reseller, Prumotech, looking for a flexible and more accurate solution. The solution presented was the FreeScan Combo, which has metrology-grade accuracy, reduced size, mobility flexibility and ultra-fast scanning speed.

After the demonstration carried out by Prumotech, and the financial proposal presented, YUTAKA made the decision based on the high capacity that the FreeScan Combo presented during the tests, in addition to the investment cost being highly attractive.

A YUTAKA employee scans a part with the FreeScan Combo

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

Automotive Exhaust Converter Inspection with FreeScan Combo

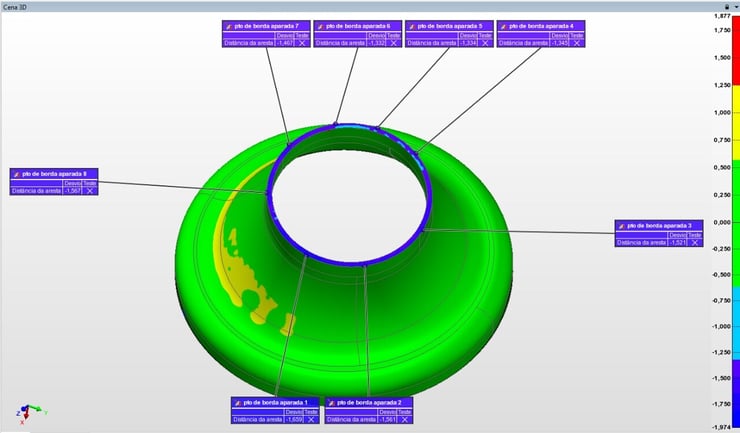

With the FreeScan Combo, YUTAKA has increased productivity and reduced inspection costs due to the flexibility of the 3D scanner.They can capture the 3D mesh in minutes, using the FreeScan Combo with 1.86 million points per second capability. Combined with Polyworks software, YUTAKA can now deliver a complete inspection solution to their customers. In addition, they can go directly to their customers’ sites, achieving faster service and response times.

Inspection details

Results Not Only Faster, But with Much More Quality and Accuracy

In its early work with the FreeScan Combo, YUTAKA noticed the high quality of the 3D meshes generated for inspection and quality control. The FreeScan Combo has metrology-grade resolution and accuracy. In addition, the FreeScan Combo is able to pass the VDI/VDE 2634 accuracy certification in SHINING 3D's ISO 17025 accredited accuracy laboratory.

By replacing fixed 3D scanning with the flexible, high-precision FreeScan Combo, YUTAKA achieved faster, more efficient inspections that enhanced service response times and quality control.

If you’re ready to boost efficiency and quality in your inspection processes, consider the FreeScan Combo!

FreeScan Combo

The powerful FreeScan Combo packs dual light sources in an ultra-compact shell, measuring just 193x63x53mm. It's equipped with both blue laser and infrared VCSEL technology and weighs in at only 620g.

- Blue laser & Infrared light

- 4 Scanning modes to cover all types of workpieces

- Lightweight