Case Studies

Published on Dec. 6th 2024

How Mold Manufacturer Achieves Rubber Mold Producing Accuracy with FreeScan Trio

PT. AFTECH RAND PERKASA continuously faced challenges in the precise production of rubber molds until they were introduced to 3D scanning technology. After using several other brands of 3D scanners, they have now chosen SHINING 3D's FreeScan Trio to enhance their workflow and meet their high standards of accuracy.

Introduction

Accuracy is crucial in mold manufacturing to ensure the quality of the final product. PT. AFTECH RAND PERKASA continuously faced challenges in the precise production of rubber molds until they were introduced to 3D scanning technology. After using several other brands of 3D scanners, they have now chosen SHINING 3D's FreeScan Trio to enhance their workflow and meet their high standards of accuracy.

About the Client

Name: PT. AFTECH RAND PERKASA

Services: Mold Manufacturing for Injection Plastics, Rubber, Die Casting, and Precision Parts

Location: Indonesia

Need: 3D scan with high accuracy for mold design and manufacturing

Solution: FreeScan Trio

Results:

- Get highly accurate and detailed models that meet the design specification

- Data on reflective surfaces can be easily acquired

- Some parts can be scanned without markers

Why PT. AFTECH RAND PERKASA Chose FreeScan Trio?

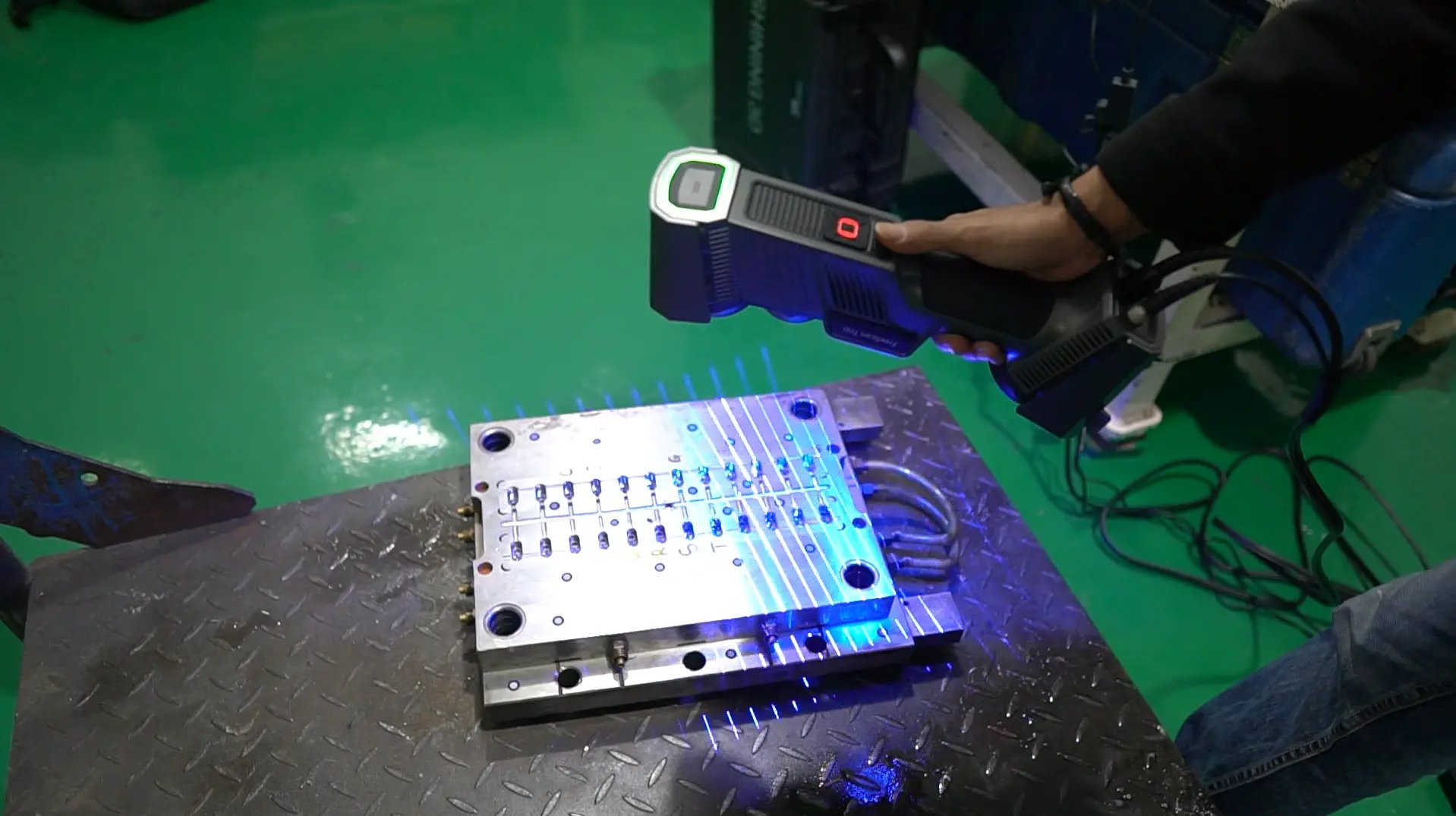

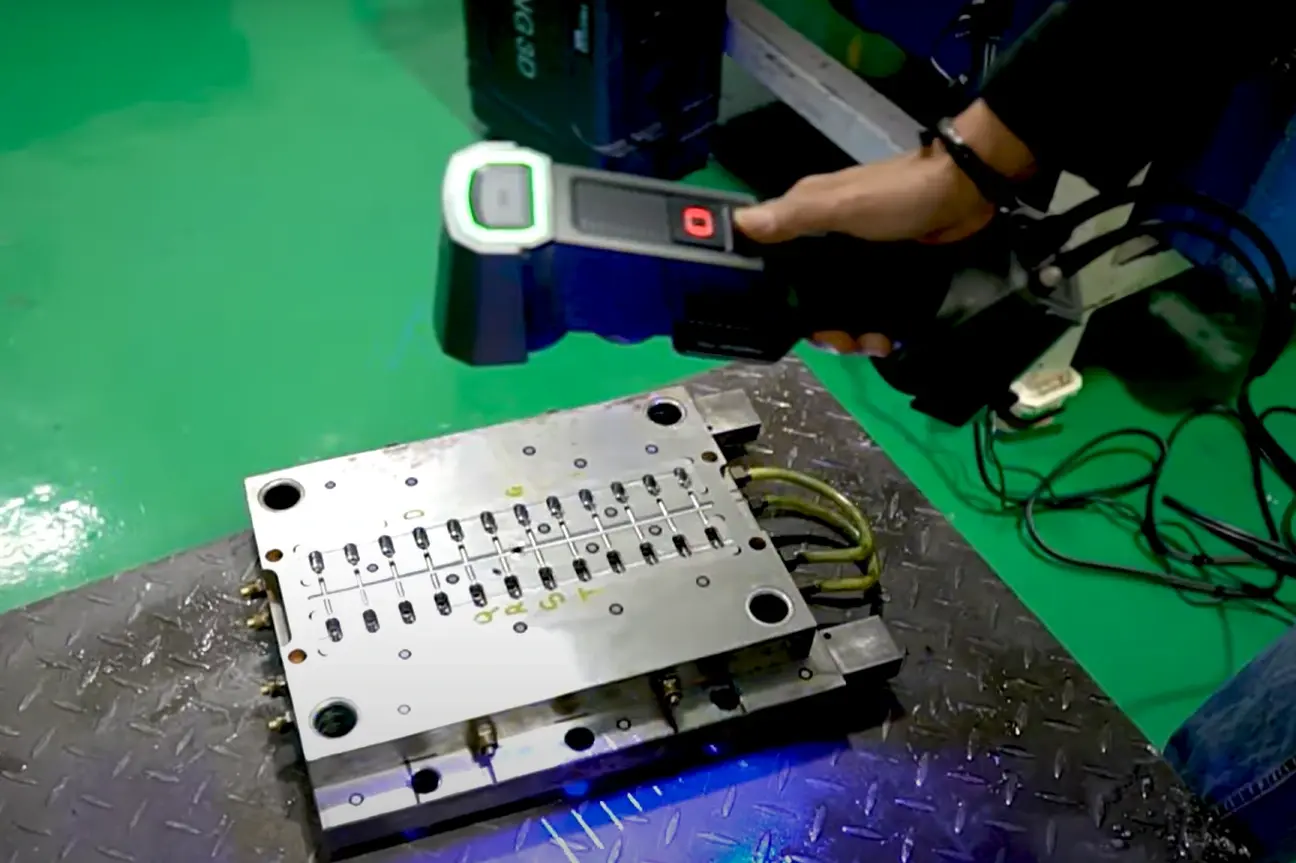

PT. AFTECH RAND PERKASA selected the FreeScan Trio from SHINING 3D due to its outstanding accuracy (up to 0.02mm) and ease of use. The laser lines are less sensitive to ambient light and thus deliver better performance when scanning reflective surfaces. In addition, when the object has rich geometric features, the 98 laser lines can offer scanning without markers.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

3D Scanning on site picture

How PT. AFTECH RAND PERKASA Use 3D Data Acquired by FreeScan Trio?

Usually, the scanned data is imported into specialized CAD software, where engineers can fine-tune the mold design and ensure it meets specifications. This digital mold is then used to create a prototype or directly guide CNC machines or 3D printers to produce the mold.

Conclusion

With advanced features, including high-precision laser scanning and detailed data capture, the FreeScan Trio has met and exceeded the company's expectations in mold manufacturing. "The final model shows the quality and precision of our designs, which enhances our marketing efforts and attracts more customers", said an engineer of PT. AFTECH RAND PERKASA.

If you want to enhance your mold production process with greater accuracy and efficiency, now is the time to consider the FreeScan Trio from SHINING 3D! Click the button below to learn more about the product and contact us.

FreeScan Trio

With its fast and innovative 98-laser-line mode, the FreeScan Trio is SHINING 3D's first marker-free laser 3D scanner. Less preparation, more efficiency.

- 98 Laser Lines, Zero Markers

- Unrelenting Accuracy and Precision

- Swift, Effortless Scanning