CASE STUDIES

Published on Apr. 16th 2025

Inspection and Quality Control of Carbon Fiber Monocoque for Hypercars with FreeScan Trak Pro2

Bugatti-Rimac employs a combination of inspection procedures, including 3D scanning, to guarantee flawless quality in production.

Hypercars represent the pinnacle of automotive engineering, where precision, quality, and zero compromises define every component. To meet these high standards, Bugatti-Rimac has integrated SHINING 3D’s FreeScan Trak Pro2 into its state-of-the-art metrology lab, ensuring flawless accuracy in its quality control process.

Rimac Campus One in Sveta Nedjela, Croatia

Bugatti-Rimac: A Fusion of Automotive Excellence

Bugatti-Rimac is a strategic joint venture between two legendary automotive brands: Bugatti Automobiles, which has over 110 years of heritage, and Rimac Automobili, renowned for its leadership in high-performance electric vehicles (EVs). Under the leadership of Mate Rimac, the company is headquartered in Sveta Nedelja and plans to transition into the €200M Rimac Campus—a next-generation facility for hypercar manufacturing and advanced EV technology development.

Rimac Automobili: Nevera

At the heart of Rimac Automobili’s production is Nevera, a groundbreaking electric hypercar with record-breaking performance. Its carbon fiber monocoque—the largest ever used in series production—is subjected to rigorous quality control to ensure each unit meets specifications. Exact measurements guarantee perfect fitting between it and any mounted elements like suspension, etc. The 200 kg structural and engineering masterpiece that serves as the backbone of the vehicle is the biggest piece that needs to be validated before production begins.

“At Rimac, precision is everything. Every component must meet the highest standards to ensure performance and safety.”

— Annamaria Hamata, Quality Analyst

Nevera’s Carbon Fibre Monocoque

Inspection of High-End Hypercars Requires High-End 3D Digitizing Solutions

Bugatti-Rimac employs a combination of inspection procedures, including 3D scanning, to guarantee flawless quality in production. After first integrating the FreeScan Trak Pro in 2023, the company upgraded to the FreeScan Trak Pro2, boosting efficiency and precision in their metrology-driven workflow.

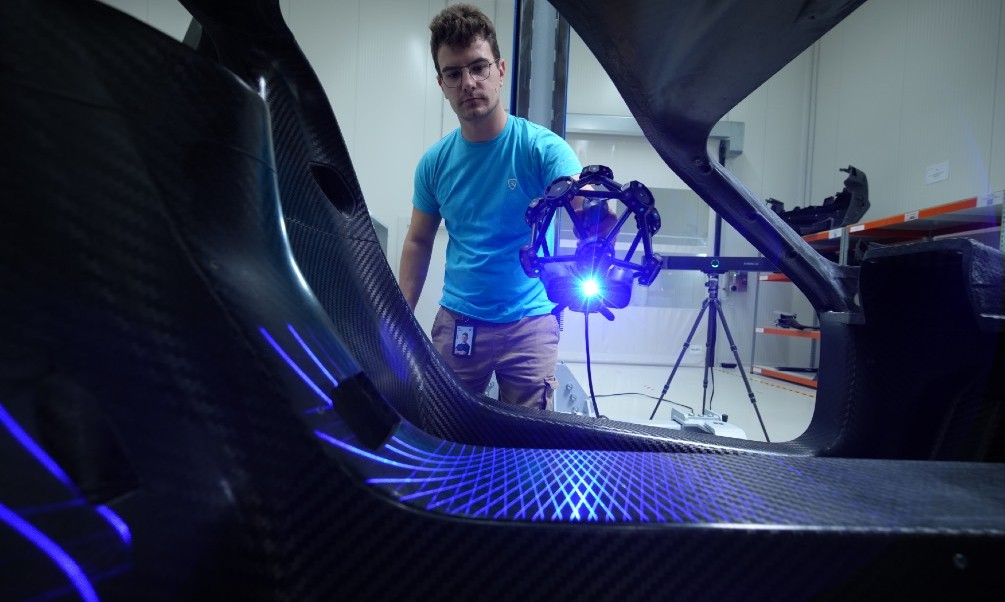

Ivan Radicevic (quality control technician of Bugatti-Rimac) is using FreeScan Trak Pro2 for monocoque scanning

3D Scanning Operation of Nevera Monocoque in the Metrology Lab

One of the most critical elements inspected is Nevera’s carbon fiber monocoque, which is the main chassis part and the literal backbone of the entire vehicle. The goal is to validate the monocoque’s production quality, align it with other carbon fiber components, and ensure the precise positioning of mounting points for the suspension, drivetrain, and chassis elements.

In this case, mounting points on the chassis, the underside, and key cockpit features were scanned using the FreeScan Trak Pro2. The system’s primary advantage is its ability to capture high-precision data without scan spray or extensive marker placement.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

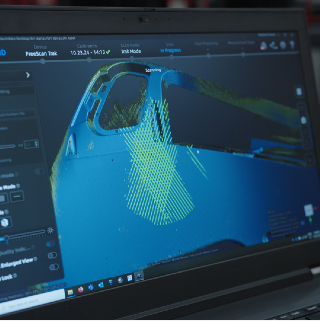

After scanning, data is processed in a 3D inspection software, where engineers verify tolerances against design specifications. With the quality control lab integrated into the production facility, potential manufacturing deviations are quickly identified and corrected, preventing costly delays.

Monocoque inspection

“The FreeScan Trak Pro2 allows us to inspect complex carbon fiber structures faster and with greater accuracy...With real-time data, we can immediately address any deviations, ensuring a perfect fit for every component.”

— Ivan Radicevic, Quality Control Technician

The Benefits of Using FreeScan Trak Pro2 in Hypercar Quality Control

Bugatti-Rimac selected the FreeScan Trak Pro2 for its exceptional accuracy, speed, ease of use, and reliability:

- Metrology-grade precision ensures every measurement meets strict tolerances.

- High-speed scanning accelerates inspections, preventing production delays.

- No scan spray or excessive markers simplifies workflow and saves time.

- Seamless software operation ensures no bottlenecks in the software pipeline.

- Reliability and expert support from SHINING 3D ensure uninterrupted operations.

FreeScan Trak Pro2 for hypercar monocoque quality control

"The FreeScan Trak Pro2 is 50% faster and 100% more accurate than its predecessor, giving us a major advantage in quality control."

—Ivan Radicevic, Quality Control Technician

By integrating FreeScan Trak Pro2 into its metrology lab, Bugatti-Rimac upholds its commitment to engineering excellence, ensuring that every Nevera hypercar meets the highest standards of quality and precision.

Conclusion

In the hypercar industry, absolute precision is not optional—it’s essential. Bugatti-Rimac’s adoption of SHINING 3D’s FreeScan Trak Pro2 highlights the growing importance of high-end 3D scanning solutions in advanced quality control workflows. With unmatched accuracy, speed, and reliability, the FreeScan Trak Pro2 is an indispensable tool for manufacturers pushing the limits of performance.

Through strong collaboration with SHINING 3D, Bugatti-Rimac continues to set new benchmarks for innovation, quality, and customer satisfaction. At SHINING 3D, we are more than happy to support Bugatti-Rimac with cutting-edge technology to propel them to the next level of excellence.

FreeScan Trak Pro2

With high precision and repeatability, the FreeScan Trak Pro2 allows for fast, accurate inspection of various part types and surfaces without the need for markers. It is the ideal metrology tool for quality control and 3D inspection.

- No Markers Needed

- Exceptional Accuracy

- Wide Measuring Range

%20is%20using%20FreeScan%20Trak%20Pro2%20for%20monocoque%20scanning.png?width=1005&height=470&name=Ivan%20Radicevic%20(quality%20control%20technician%20of%20Bugatti-Rimac)%20is%20using%20FreeScan%20Trak%20Pro2%20for%20monocoque%20scanning.png)