PR/News

Published on Feb. 19th 2025

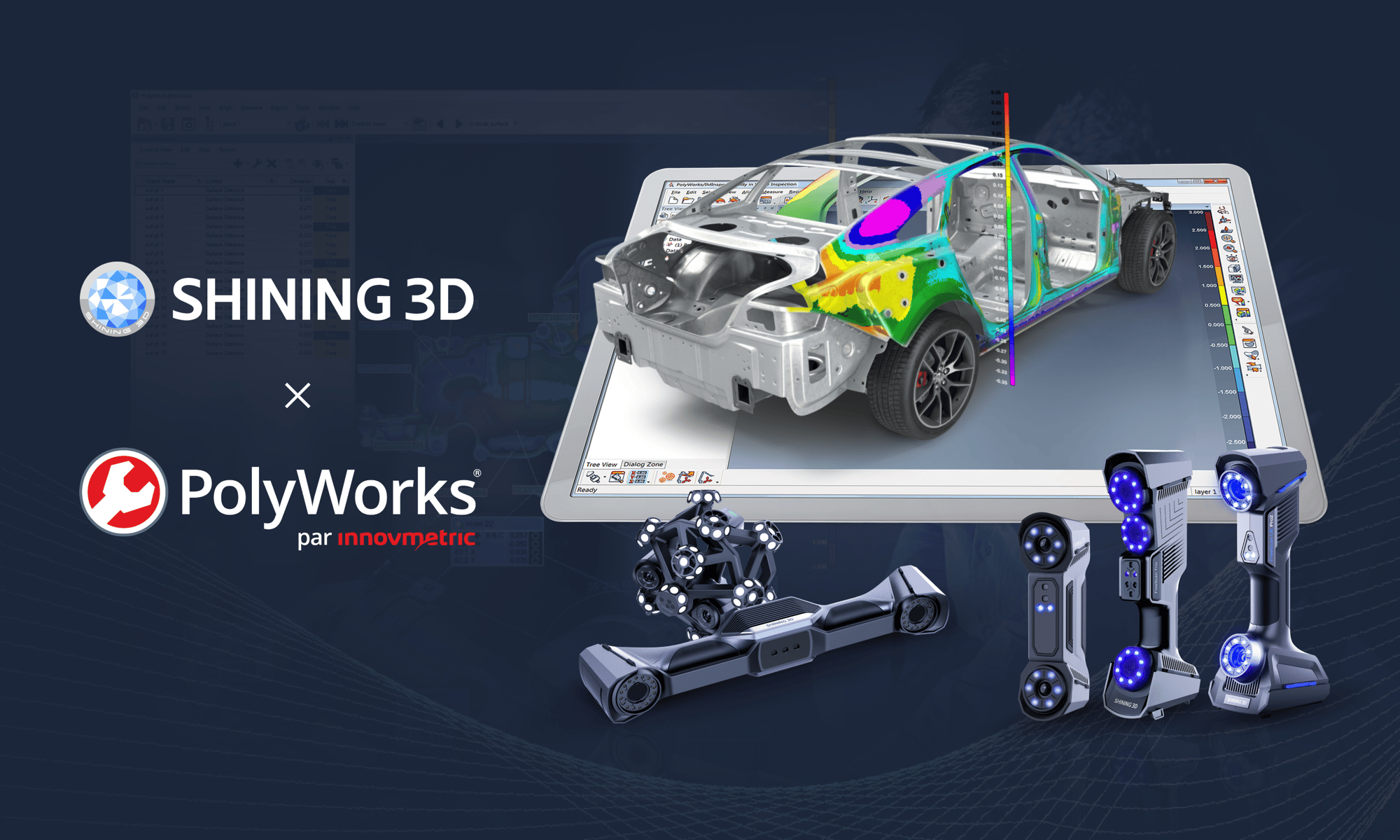

SHINING 3D Announces Global Partnership with InnovMetric

This collaboration marks a significant milestone for both companies, further empowering customers with advanced solutions for diverse 3D metrology needs.

SHINING 3D is proud to announce a strategic global partnership with InnovMetric, the creators of the PolyWorks universal 3D metrology software platform. This collaboration marks a significant milestone for both companies, as SHINING 3D becomes a global partner of the PolyWorks Inspector software, further empowering customers with advanced solutions for diverse 3D metrology needs.

“The synergies will bring extraordinary value to the automotive, civil aviation, machinery manufacturing, energy, and other industries,” states Sunny Wong, Managing Director Overseas at SHINING 3D. “Our customers will benefit from an integrated solution that enables seamless dimensional analysis and quality inspection, enhancing productivity across operations.”

The partnership unites SHINING 3D’s expertise in high-accuracy 3D scanning technologies with InnovMetric’s renowned PolyWorks Inspector software, celebrated for its universal dimensional analysis and quality control platform. This synergy is set to provide exceptional value to industries such as automotive, engineering, and manufacturing. SHINING 3D and InnovMetric customers will benefit from an integrated solution that enables seamless dimensional analysis and quality inspection, enhancing precision and productivity across operations.

"This partnership with SHINING 3D reaffirms our dedication to providing open and innovative 3D metrology solutions that foster collaboration and drive manufacturing excellence," says Abdul Aziz Saleem, Vice-President of Sales, APAC, at InnovMetric.

Through this collaboration, both SHINING 3D and PolyWorks will reach a broader audience. Together, the two companies aim to elevate industry standards and drive innovation in 3D metrology.

About SHINING 3D

Founded in 2004, SHINING 3D has been focused on the research & development, manufacturing, and application of high-accuracy 3D digital products for over 20 years. Offering accessible, efficient, and high-tech solutions, SHINING 3D is a key contributor to the 3D digital technology field. With its global influence, SHINING 3D promotes the popularization of 3D digital technology for numerous applications.

About InnovMetric

InnovMetric is an independent software development company that empowers manufacturers of every size to digitally transform their 3D measurement processes. InnovMetric revolutionized 3D metrology with the introduction of point-cloud-based dimensional inspection in 2000 and the concept of a universal 3D metrology software platform in 2006. Today, with over 18,700 customers in 99 countries, and the world’s largest industrial manufacturers having adopted its PolyWorks® solutions as their standard 3D metrology software platform, InnovMetric is focusing on creating next-generation digital data and process management technologies. Headquartered in Quebec City, Canada, InnovMetric is a multinational organization with 500 employees dedicated to bringing 3D measurement data at the heart of enterprise manufacturing processes.

PolyWorks

PolyWorks Inspector is a universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.