CASE STUDIES

Published on Jun. 14th 2024

Enhancing Precision in Smartphone Glass Panel Inspection with OptimScan 5M Plus

Smartphone glass panel inspection requires precise methods due to the panels’ small size and delicate structure. However, the methods of calipers and coordinate-measuring machines (CMM) fail to provide the necessary accuracy. SHINING 3D’s OptimScan 5M Plus desktop 3D scanner offers a non-contact, high-precision, and high-efficiency solution for inspection needs.

Smartphone glass panel inspection requires precise methods due to the panels' small size and delicate structure. However, the methods of calipers and coordinate-measuring machines (CMM) fail to provide the necessary accuracy. SHINING 3D's OptimScan 5M Plus desktop 3D scanner offers a non-contact, high-precision, and high-efficiency solution for inspection needs.

Understanding Smartphone Curved Glass Panels

Smartphone curved glass panels are integral to modern phone designs, offering functional benefits such as better ergonomics and immersive displays. A curved glass panel is processed by hot pressing bending. After processing, the whole curved surface will have a certain deformation. Mastering the deformation state and deformation trend of the curved surface is the key to adjusting the process parameters and speeding up the production process.

Pain Points of Smartphone Curved Glass Panel Inspection

Inspecting curved glass panels is challenging due to their small size, thinness, and curvature. Traditional tools like calipers struggle to provide accurate data. In addition, the panels are easily deformed under pressure. Contact measurement methods, such as CMM, introduce errors and are inefficient for high-volume production environments.

Curved Glass Panel Inspection with OptimScan 5M Plus

3D Scanning - Get Complete 3D data within 1 Minute

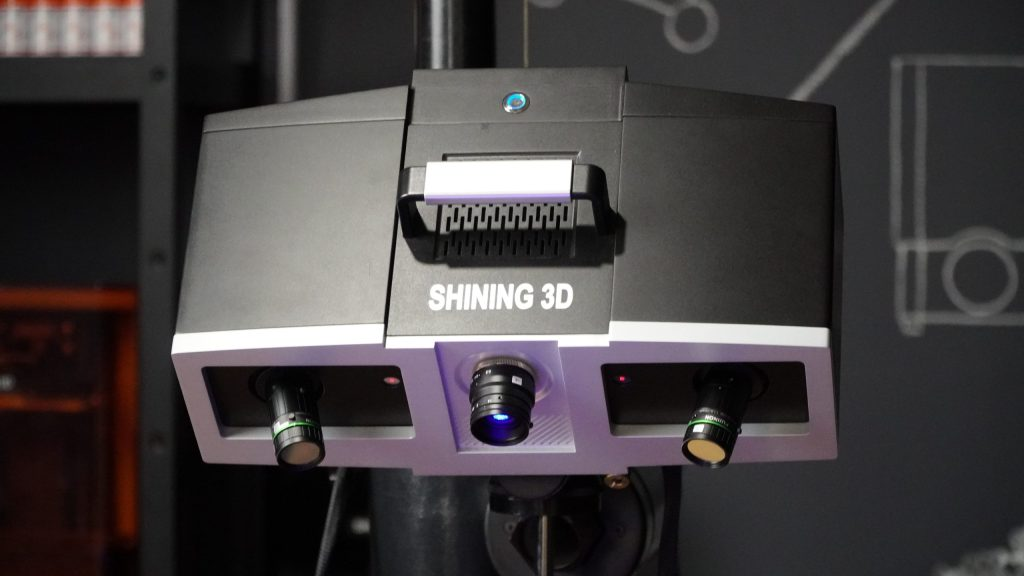

OptimScan 5M Plus

SHINING 3D's OptimScan 5M Plus solves the challenges faced by calipers and CMMs once and for all:

- 3D scanning acquires 3D data in a non-contact manner. This method eliminates the risk of panel distortion.

- The OptimScan 5M Plus is characterized by high accuracy (up to 0.005mm) and stable repeatability, with a single scanning speed of ≤1.5 seconds, and with an automatic rotary table, it is able to efficiently and accurately acquire three-dimensional data in less than one minute.

- OptimScan 5M Plus adopts a 1080P optical machine and 5 million high-resolution industrial cameras to acquire complete and smooth data quality.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

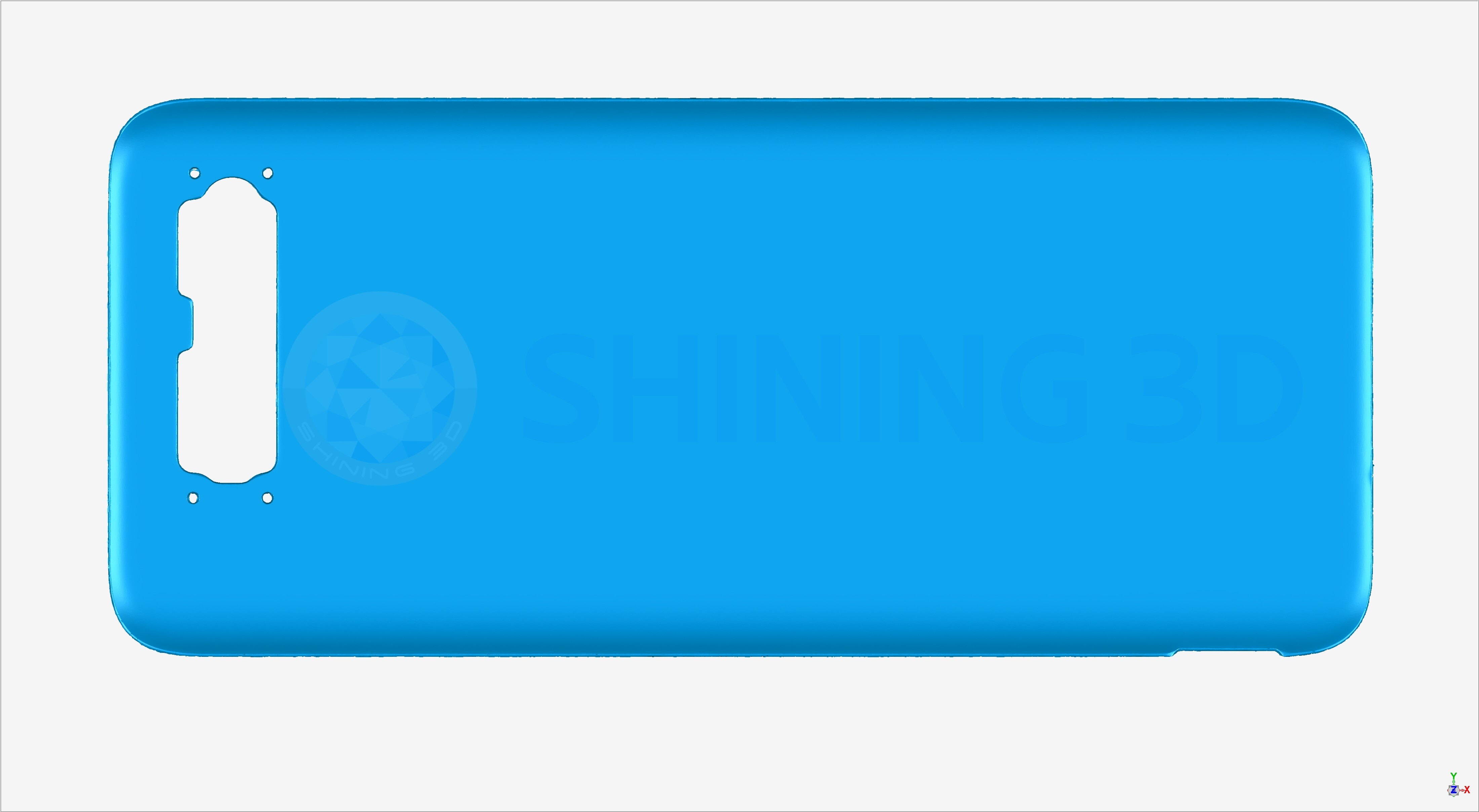

Smartphone curved glass panel 3d data

3D Inspection - Auto Output Inspection Report within 1 Minute

After completing the first inspection path programming (about 10 minutes), we will import the 3D scanning data into the inspection software. Within 1 minute, the inspection software can automatically output the inspection report and generate the chromatogram, which intuitively shows the deformation location and accurately analyzes the curvature of the surrounding curves, and so on.

Analysis of curvature variations of four-sided arcs

Upper and lower short side analysis

Left and right long side analysis

R-angle analysis

Appearance deformation trend analysis

Overall deformation analysis

Cross-sectional analysis

In conclusion, the OptimScan 5M Plus overcomes traditional method limitations of smartphone curved glass panels with high accuracy and efficiency. It also ensures precise deformation analysis, optimizing manufacturing processes and enhancing production efficiency.

Do you need help with the challenges of inspecting delicate curved glass panels? Discover how SHINING 3D's metrology solution can enhance your quality control process and ensure superior product quality.

OptimScan 5M Plus

OptimScan 5M Plus is a High-precision 3D inspection scanner with narrow-band blue light source and upgraded high-resolution industrial lens, it provides better detail performance in scanning and smoother data quality.

- High Accuracy up to 0.005mm

- High Resolution Cameras

- Multiple Scan Ranges