CASE STUDIES

Published on Dec. 26th 2024

Thai Manufacturer Cuts Aircraft PMA Components Inspection Time to Half a Day with SHINING 3D Metrology Scanner

This case study explores how the adoption of 3D scanning technology transformed AMT’s inspection workflow and highlights the advantages of partnering with SHINING 3D.

Air Mount Technic (AMT), a manufacturer of aircraft components in Thailand, has successfully streamlined its inspection processes using the FreeScan Combo+ scanner from SHINING 3D. This solution has enabled AMT to reduce the inspection time for their Parts Manufacturer Approval (PMA) components from days to just half a day. This case study explores how the adoption of 3D scanning technology transformed AMT’s inspection workflow and highlights the advantages of partnering with SHINING 3D.

AMT Company Overview

Air Mount Technic specializes in the design, certification, and production of critical aircraft components, including Class 3 PMA parts for wheels, brakes, and helicopter systems. The company also produces aerospace chemicals, cleaning devices, and starting systems tailored for aviation needs. AMT’s engineering department serves as the core of its operations, ensuring all products meet rigorous safety and regulatory standards. Based in Pathumthani, Thailand, AMT’s 12-member team is dedicated to delivering reliable and innovative solutions to the aviation industry.

The Challenge: Manual and CMM Inspections

Before adopting 3D scanning technology, AMT relied primarily on Coordinate Measuring Machines (CMM) for PMA component inspections. While CMMs are known for their precision, they pose significant challenges, especially for complex, curved parts. The process required extensive setup, including jig and fixture design and programming, which could take up to three days per part. Furthermore, CMMs demanded significant operator expertise and were less efficient when dealing with parts requiring multiple measurements from different angles.

Inspection with a CMM, a time-consuming method

Inspection with a CMM, a time-consuming method

These factors led AMT to seek an alternative that would improve efficiency and reduce turnaround time.

The Decision to Adopt 3D Scanning

The shape of the parts AMT works with was well-suited for 3D scanning. The team evaluated various options and ultimately decided on SHINING 3D’s FreeScan Combo+, choosing it for its speed, ease of operation, and lightweight design. The scanner’s ability to quickly capture data without the need for extensive setup or jigs made it a perfect fit for AMT’s workflow.

Discover the product you're looking for

- Full specifications

- Using scenarios

- Key features

- Even comes with a bundle!

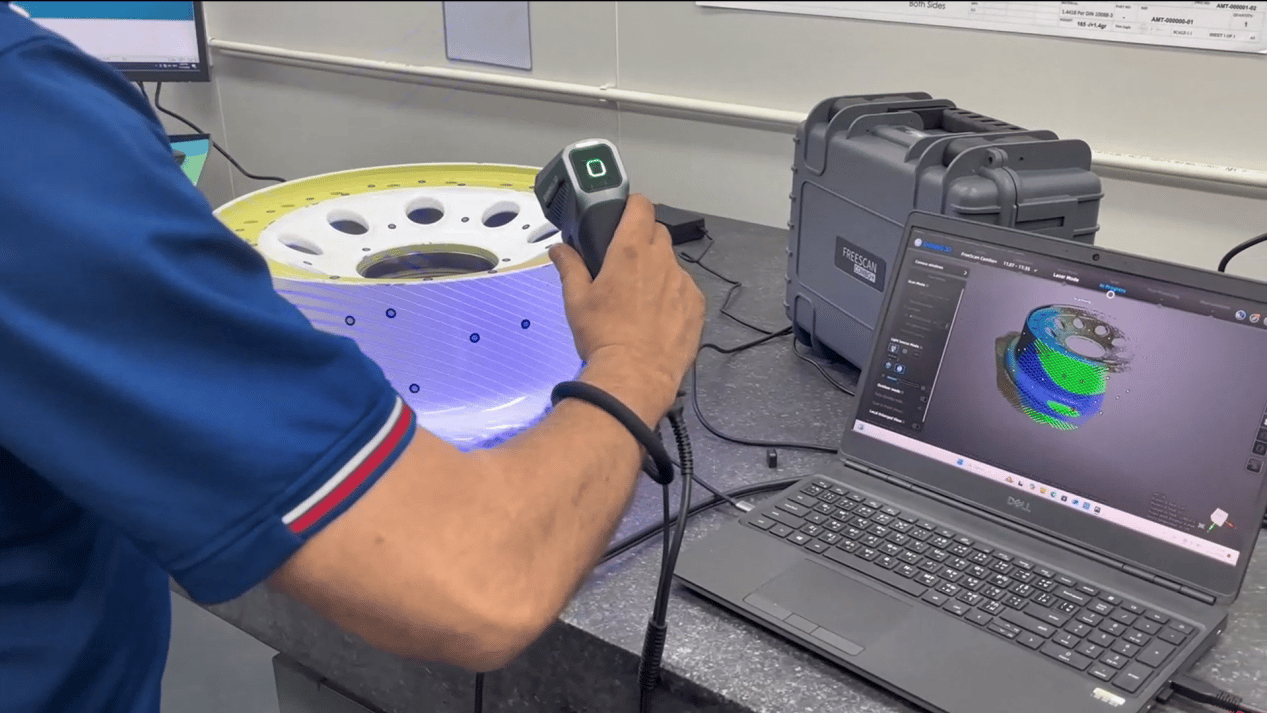

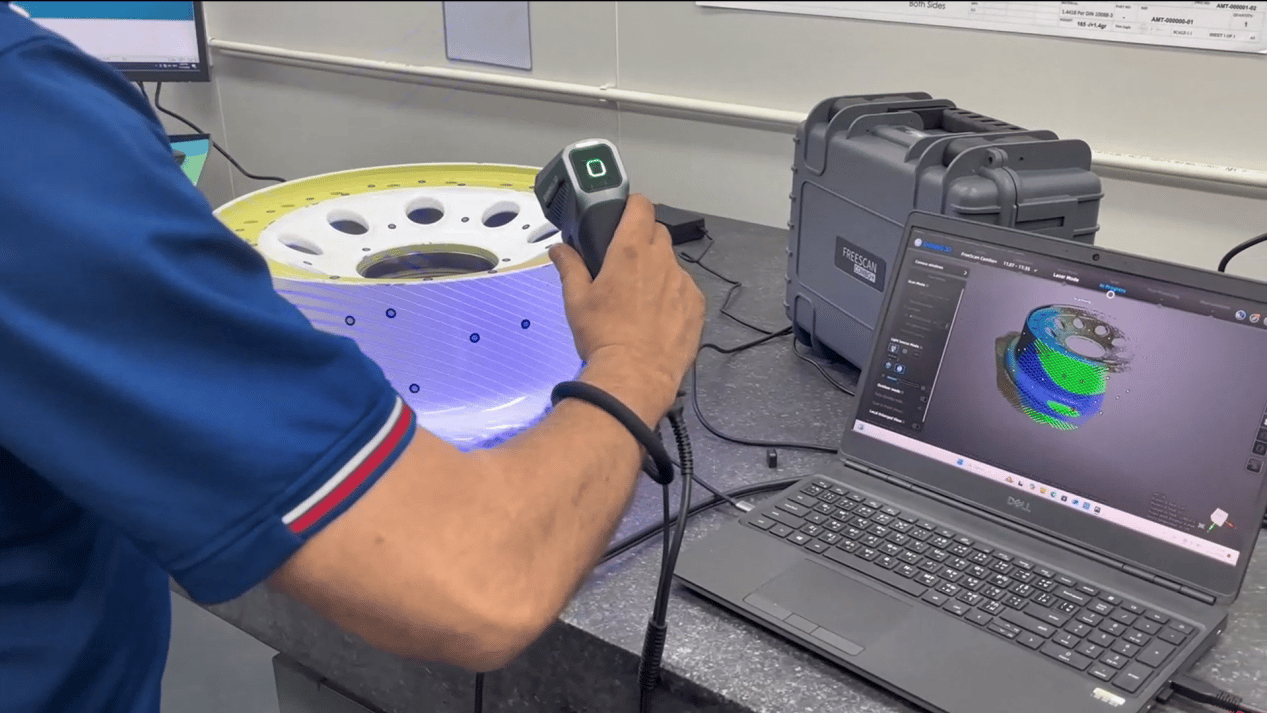

3D Scanning with FreeScan Combo+

By adopting the FreeScan Combo+, AMT was able to address several key pain points:

- Reduced Setup Time: Unlike CMM, the FreeScan Combo+ does not require detailed programming before scanning. For the same part, a CMM would take 2-3 days to set up the program and start collecting data. With the FreeScan Combo+, all you need to do is connect the power supply to the computer,and the data can be captured in less than half a day.

- No Jig or Fixture Requirement: The 3D scanner’s ability to collect data without the need for part fixation or complex jigs streamlined the process. In some cases, parts inspection by CMM requires the use of multiple fixtures, which can take up to three days to design and manufacture. However, with the 3D scanner, you have the freedom to change the angle of the scanner for scanning or to flip the part over.

- Portable and Ease of Use: The FreeScan Combo+is a real lightweight scanner that can be taken anywhere for scanning easily. That's what CMM can't handle. It was also recognized for its user-friendly interface. AMT found it easy to operate, even for team members without specialized skills in 3D scanning. “You'll only need half a day at most to familiarize yourself with how to use it,” an employee from AMT said.

3D data acquired by FreeScan Combo+

3D data acquired by FreeScan Combo+

Why Choose SHINING 3D?

In addition to the advantages of the FreeScan Combo+ itself, AMT praised SHINING 3D for their professional demonstration of the scanner and their exceptional customer service. The team appreciated the friendly, knowledgeable approach of SHINING 3D’s staff and their ability to answer all questions thoroughly. AMT also noted that SHINING 3D had a long-standing presence in Thailand, further reassuring them of the company's reliability.

Looking forward, Air Mount Technic plans to continue exploring how 3D scanning can enhance other areas of their operations, such as prototyping, quality assurance, and even improving their design processes.

Are you wondering in which workflow segment 3D scanning can help you? Please do not hesitate to contact us for a customized solution!

FreeScan Combo

The powerful FreeScan Combo packs dual light sources in an ultra-compact shell, measuring just 193x63x53mm. It's equipped with both blue laser and infrared VCSEL technology and weighs in at only 620g.

- Blue laser & Infrared light

- 4 Scanning modes to cover all types of workpieces

- Lightweight